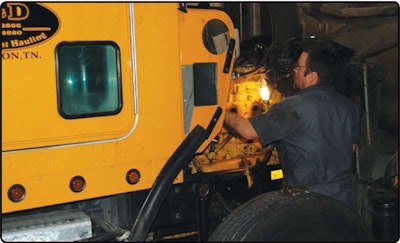

Any preventive maintenance service presents a good opportunity to have the engine and other components inspected for wear.

Any preventive maintenance service presents a good opportunity to have the engine and other components inspected for wear.Don’t let a single price tag drive your decision to rebuild, repair or replace a failing truck or component. Count all the costs and make the right choice.

When warning signs that a major component, an engine, or your entire truck needs serious attention, it often raises a tough question: Should you rebuild, repair or replace it?

You don’t have to settle for an educated guess or a knee-jerk reaction to initial cost. By assessing the truck’s value, examining costs associated with various decisions, and considering other factors, you can methodically arrive at a well-informed choice.

Costs such as $18,000 to $20,000 for an engine overhaul, $5,000 for overhauling the transmission and $3,000 to $4,000 to overhaul the rear end might push you toward purchasing a newer truck. That could be the best decision, but the size of such numbers alone isn’t enough to make that call.

“Maintenance is predictable,” says John Dolce, a maintenance expert and fleet adviser who’s affiliated with Wendel Duchscherer, a technical consulting firm. By the sixth year of ownership, the annual cost of parts and labor often exceeds 30 percent of the vehicle’s value, and that share continues to grow, he says.

Annual maintenance spending on that aging vehicle eventually will top its resale value, according to Dolce’s calculations, based on the performance of fleets he’s worked with. “One year it’s going to go to 150 percent in maintenance as share of value,” he says. That would be the case if you spent $30,000 for an engine overhaul and other major repairs on a truck worth $20,000. “That’s not cost-effective, because you’re not getting the reliability out of that piece of equipment.”

Dolce says the 30 percent maintenance spending could be a marker for deciding the following year whether to replace your vehicle or rebuild it. You’ll have to compare the costs of buying and operating a new or late-model truck with the expense of doing an in-frame engine rebuild that would extend the truck’s life for several more years, he says.

Another benchmark approach is maintenance spending on a cost per mile basis. Bill McClusky, a consultant with owner-operator financial services company ATBS, estimates average maintenance costs of about 10 cents a mile for a used truck of around 500,000 miles or more and 6 cents a mile for a newer vehicle with up to 250,000 miles.

“Exceeding 15 cents per mile in maintenance costs should trigger an evaluation of the major components of the truck,” he says. McClusky says upgrading your vehicle may force you to take on a truck payment or increase an existing one, but it’s wise if it ultimately proves cheaper than what you’re spending on maintenance.

Another potential measuring stick is mileage. At 800,000 or more miles, an engine overhaul could be imminent, especially if your engine starts “sucking oil,” Dolce says. “When you start to use four or five quarts a day or more, that’s telling you that you have wear on the engine. You can continue to do that and all of a sudden you lose oil pressure and blow the engine. You need to find the problem to preserve the core.”

A fluids analysis could indicate whether your truck may have other major maintenance problems down the road. “There’s no sense in investing $18,000 to $20,000 in an engine overhaul if the transmission and differential are close to being worn out,” McClusky says.

Dale Wiederholt, owner-operator of Wiederholt Transport in Hazel Green, Wis., runs eight trucks and shies away from trading them. “Unless it’s got a lot of chronic problems, I’d rather rebuild than replace it,” he says. “Every time you turn a truck over, you have hidden costs and time delays that you can’t generate revenue with.”

Gordon Bow, who runs under his own authority as Mortgage Hill Trucking, advises determining the truck’s current condition and longevity before deciding whether to pour money into it or trade it. “If it gets down to $35,000 or $40,000 in value and you have to stick $15,000 or $20,000 into it, and if you know everything else is in really good shape and not going to give you trouble for another two or three years, then do it,” he says.

Lenny Bower of Lewisberry, Pa., who’s leased to Fraley & Schilling, says you should pay attention not only to how much you spend on maintenance but where the dollars are going. For example, up until 2008, he figures he spent less than a couple thousand annually on his 2003 Western Star. In each of 2008 and 2009, however, he says he spent about $7,500, repairing brake shoes and drums and replacing the alternator, batteries and two injectors.

“I really think spending will slack off now because I had the motor opened up and they looked underneath,” says Bower, Overdrive’s December 2009 Trucker of the Month. “I ran into one guy running a 35-year-old Kenworth. If he can run that long, why can’t I?”

Bower says he relies on oil analysis to tell him “when to overhaul the engine because different metals will start showing up,” he says. “My truck has 701,000 miles on it. The question is how much longer it will last before I have to do the pistons, cam bearings and other parts that have metals that show up in there.”

For a truck driven heavy mileage over the road, most maintenance spending over the years is predictable, allowing you to make informed decisions when confronted with a major mechanical problem.

For a truck driven heavy mileage over the road, most maintenance spending over the years is predictable, allowing you to make informed decisions when confronted with a major mechanical problem.Choosing to rebuild

Wiederholt last bought a new truck in 2000. When he looks for a used truck, he examines the vehicle’s “rebuildability,” just as he does when his trucks need major work.

He and his shop manager review a truck’s mileage, its application, past and anticipated maintenance problems, and the cost to repair. Only then do they decide whether it’s worth that cost.

“If I can rebuild the motor and the front end is in tight shape and we haven’t had to spend a lot of money on a new radiator, charge air coolers or a clutch or a transmission lately, I’ll do it a little bit at a time,” Wiederholt says. “When I rebuild a motor, I try to do as much in frame as possible.”

He’s rebuilt two trucks using glider kits. He took the old engine, transmission, suspension, rear ends and fifth wheel and matched them with a kit containing a new cab, frame rail chassis and front axle. “On each one I saved approximately $30,000 over the price of a brand-new truck of similar vintage and specs,” he says.

Wiederholt’s shop will rebuild most of the truck except for transmissions, which he farms out, and rear ends, which he will swap out for a remanufactured alternative. “If we put in a new remanned rear end, we’ll replace the bearings and hubs and we’ll do a new brake job,” he says. “It’s not just a repair; it’s a rebuild on the go.”

On an in-frame overhaul of a Detroit Diesel Series 60, you can expect to spend $15,000 to $16,000, estimates McClusky of ATBS. To replace the engine but not all of the components will run about $22,000. It’s usually cheaper to rebuild transmissions and differentials unless they’ve experienced a catastrophic failure, he says.

Not all rebuilds are the same, cautions Mike Betts, CEO of Betts Spring Co. of Fresno, Calif. With a transmission, ask if all of the components have been rebuilt or just a few, and whether the rebuild comes with a warranty.

Betts says determining whether to repair or rebuild or replace comes down to cost. “If you can’t save 25 percent over the cost of a new part, you may not want to buy the rebuilt part.”

Dolce notes that one of your biggest cost items is your tires, and the best way to get more mileage and save money is to recap your casings. When tires in any of the three positions wear down to around 5⁄32nds, it’s time to recap. He recommends “cold caps” – where the temperatures of the casing and the new tread are the same when they bond – at $150 to $175, over “hot caps,” which are better suited for low-speed applications, at half the price. “Recap your own casings, not someone else’s,” he says.

Owner-operator Lenny Bower uses oil analysis to help him decide when to overhaul his engine or make other significant repairs.

Owner-operator Lenny Bower uses oil analysis to help him decide when to overhaul his engine or make other significant repairs.Other components that can be rebuilt are brakes, steering mechanisms and suspensions. Measure brake shoes and drums to decide if they need to be replaced, Dolce says. If you can avoid scoring of the drums and use your existing shoes, you’re many dollars ahead.

A good core is key to rebuilding electrical parts like the alternator and starter. Using a diagnostic tool costing $1,200 to $1,500, you can check the amperage to see if the components are drawing too much. If you can head off the premature deterioration of the starter’s core, Dolce says, you can buy a rebuilt unit for $750 or less, about half the cost of a new one. “If it gets three-fourths the life of a new starter, it’s worth doing,” he says.

Choosing to replace

Owner-operator Gordon Bow usually believes new is better. If he’s having a brake job done, replacing springs or repairing a transmission or differential, everything will be new.

“When it comes to a transmission or differential, nowadays most are going to get 750,000 to a million miles,” Bow says. “I would not put in new parts and new bearings in half of it and not do it all. If there’s any doubt in my mind that any part of that housing isn’t going to hold a bearing snug, then I would go brand new, especially if you’re going to keep the truck” for another 500,000 to 750,000 miles.

But it’s not always an open and shut case with Bow, especially with an engine. Once he put a new engine in an aging truck that was later totaled in an accident. The insurance settlement was for $7,000. “I didn’t feel I could afford a new truck or wanted a truck payment, but in the long run I would have been better off getting a truck and payments,” he says.

After the accident, he bought a new truck. Within six months, he says the new truck with new technology and better fuel economy was “pulling me out of the debt of the old truck and being out of work for three months.”

When deciding what to do with components such as the turbo, air compressor, alternator and air dryer, Lenny Bower will usually opt to replace with new. “Cheapest isn’t always your best value,” he says. “You can recore radiators, but these days you can buy brand-new for what you spend to take it out and wait a day or two to have it recored.”

When it comes to alternators or starters, Betts doesn’t recommend rebuilding. “There’s minimal savings with the rebuild and you’re getting a warranty with new parts,” he says. “Determining value depends on the component cost, longevity of the parts, warranty and how long you’re going to own the truck.”

Owner-operator Bow says repairing items one at a time costs more in the long run. Instead of replacing a single liner or piston, spend the extra few hundred dollars and replace all six pistons. “You start putting new parts against old parts in an engine, and the good one is going to take more of the load than the other five,” he says. n

Deciding factor: Cost per mile

Maintenance consultant John Dolce uses cost per mile as a way to compare the merits of repair, rebuild or replace. In this example, a new alternator would last 150,000 miles, while the rebuilt part would last 100,000 miles. The cost per mile for covering the truck’s remaining longevity of 300,000 miles is slightly less when using the rebuilt components.

NEW: Parts: $600 x 2 alternators = $1,200

Labor: $75 x 4 hours = $300

Total cost $1,500

Cost/mile $0.0050

REBUILT: Parts: $300 x 3 alternators = $900

Labor: $75 x 6 = $450

Total cost $1,350

Cost/mile $0.0045

California regs encourage replacement

Upgrading to a new or newer used truck may become necessary if you’re running in California, whose proposed emissions regulations are likely to get stricter and stricter.

“In the next five to six years, California’s going to be a big consideration if they get these regulations in place,” says ATBS’s Bill McClusky. “It’s going to be tougher to run older trucks in there — the pre-2004 trucks, even up to 2007 models. It’s going to be a big expense to retrofit those trucks.”

What’s more, California emissions regulations have in the past been readily adopted by up to 13 other states.

McClusky says he works with ATBS client owner-operators to stretch more miles out of their existing rigs to allow them to eventually afford, in a year or two, a 2010 truck with 200,000 to 300,000 miles. To assist owners, ATBS has developed a program patterned after the aviation industry to inspect components and catch them before they fail. The firm maintains a database of each client’s truck and its condition.

“We know what life expectancies for these components are,” McClusky says. “When they are reaching these points, the next time the operator is in for an oil change, take a look at that turbocharger to see if it’s at its wear limit. More than preventive maintenance, it’s predictive maintenance.”