Stay out of trouble with the DOT through careful inspections and diligent routine maintenance.

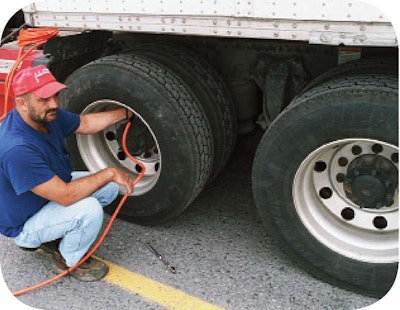

Checking tire pressures with a good gauge will head off citations for low inflation pressure as well as prevent many types of tire damage that net citations.

Checking tire pressures with a good gauge will head off citations for low inflation pressure as well as prevent many types of tire damage that net citations.If you think getting put out of service for an equipment violation is likely to involve DOT inspectors finding something complicated or unexpected, think again. Ten percent of out-of-service violations involve simple tire problems, says Commercial Vehicle Safety Alliance Deputy Executive Director Collin Mooney.

Furthermore, the Compliance, Safety, Accountability enforcement program penalizes carriers’ safety rankings for all violations. Of the 25 most common recorded by inspectors, two involve tires directly and are high-severity-weight violations, carrying 8 out of a possible 10 points. In fact, most tire violations are high-weight infractions. While simple underinflation merits only 3 CSA points, these common violations incur 8 points: running a drive or trailer tire with tread below 2/32 of an inch, running a tire with fabric exposed, and audible leak.

Time weighting means each violation’s weight will be multiplied by three in safety scoring for six months after it occurs. Thus frequent high-weight tire citations, as well as a failure to repair problems, will have immediate negative consequences for you or your carrier’s ranking in Vehicle Maintenance, one of CSA’s seven Behavioral Analysis and Safety Improvement Categories. Potential results are more inspection scrutiny at weigh stations, hassle from your leasing carrier and, ultimately, reduced business.

Bottom line: Do your pretrip inspections consistently. If you have hired drivers, get them to do the same.

PRIORITY 1:

Inflation maintenance

Using an inexpensive tread depth device is one way to make sure your tire meets the standard for minimum depth.

Using an inexpensive tread depth device is one way to make sure your tire meets the standard for minimum depth.Inflation pressure is the most critical part of a pretrip inspection, says Goodyear Marketing Communications Manager Tim Miller. “Proper inflation pressure will help prevent wear and damage, and helps eliminate casing durability concerns. Underinflation may be the cause of much of the visible damage they are looking for in an inspection.”

Running a tire low on air is just as bad as running a diesel engine with low coolant or a clogged radiator. Tires generate tremendous heat when they run because continual flexing is necessary for them to give a smooth ride. Pressurized air creates much of their structural strength and limits that flexing. When the pressure’s too low, flexing – and heat – grow by leaps and bounds. The result is softer, overheated metal cords. When a broken cord pokes through the sidewall, it’s grounds for a citation.

Always use a calibrated inflation gauge to get the necessary accuracy. The old method of thumping a tire doesn’t work, says Curtis Decker, commercial tire product development engineer for Continental Tires.

Guy Walenga, Bridgestone America’s director engineering commercial products and technologies, suggests replacing the valve stem core each time a tire is serviced, and using quality poly-carbonate or steel stem caps with good rubber seals to help retain pressure.

Other aids to pressure maintenance include tire monitoring and automatic inflation systems. They are particularly helpful with maintaining pressure on inside duals. When duals are mismatched because of a pressure difference, it can quickly lead to damage that will yield a citation.

PRIORITY 2:

Inspection checklist

Here’s a checklist based on the basic Commercial Vehicle Safety Alliance inspection criteria.

Tread damage (left) and casing damage that exposes fabric (right) do not have to be this severe to merit an out-of-service order.

Tread damage (left) and casing damage that exposes fabric (right) do not have to be this severe to merit an out-of-service order.• Look for significant bulges, Mooney says, often indicative of an approaching failure where cords are broken and forcing the sidewall out. Don’t confuse this with a bulge of fresh rubber vulcanized to the sidewall to seal off a puncture. When these don’t bulge more than 3⁄8 of an inch, they are OK. Some inspectors carry a gauge that can measure them, says Miller.

Poor repairs are a significant source of citations, says Doug Jones, Michelin Americas’ customer engineering support manager. He also notes the big fleets with their own shops tend to jettison a tire that can’t be fixed easily. But small operators sometimes find a shop that will repair a tire that’s too severely damaged or fail to perform a difficult repair properly.

• Give the tread a careful check with a tread depth gauge. Jones says that irregular wear of a tire that has good tread in most areas may still cause it to flunk the tread depth test. A spot that’s worn below 4⁄32-inch on a steer tire in two adjacent tread section, or below 2⁄32-inch on a drive or trailer tire, can get you a citation.

• Make sure the tire is not rubbing on the vehicle or in contact with a dual tire next to it because of improper mounting.

• If the truck is loaded near its weight limit, make sure the tires are of the proper weight ratings for the gross combination weight. Tires carrying more than rated weight can overheat and fail, so this will get you a citation. Mooney says this problem is less likely to attract attention in a standard roadside inspection than at a weigh station.

• Remove any objects trapped between tread sections, Miller says. Such objects often lead to serious damage to the tread. Jones says to look down into the grooves for significant cracks or the appearance of cords, symptoms indicating the tire needs to be replaced. Use a flashlight for better visibility.

• Check for chunking or tearing of the tread, Decker says. Run your hand across the tread carefully. Do you feel sharp edges? It’s a sign of irregular wear. Check further to ensure tread depth is adequate across the tire.

PRIORITY 3:

Good vehicle maintenance

For maintenance beyond the pretrip, certain procedures can help head off problems, especially related to irregular wear and uneven tread depth, that could result in a citation.

“Regular alignment will cover the majority of tire issues,” Decker says. “When it comes to items such as bearing maintenance and damper maintenance, that’s where you see the best fleets really separating themselves from the pack. It’s so tempting to save costs in the short term by skimping on regularly scheduled preventive maintenance.”

Don’t wait for tire trouble to signal the need for work on the chassis. Do it regularly so your tires will last longer.

Regular alignment means not only setting the toe-in and checking caster and camber on the front axle, it means total vehicle alignment. The latter refers to lining up the drive axles with the centerline of the tractor, and lining up the trailer axles with the kingpin. Misalignment leads quickly to irregular wear, along with wasting fuel.

Wheel bearing maintenance is critical because loose bearings lead to irregular wear of the tread and worn spots that can also leave you shy on tread depth, even on newer tires. Proper, even mounting on the rim, as well as wheel balance, and shock absorber (damper) maintenance, Decker says, will also help eliminate irregular wear and low tread depth areas by preventing the tire from hopping down the road.

“Specifying the correct tire for a given application will also help to avoid problems,” he notes.

“Getting drivers to perform a good pre-trip is only the first step,” Walenga says. “If he finds a problem, you need to repair the tire before the truck moves. Having spare tires already mounted for quick change can help get the truck on the road fast and avoid the temptation to send it out with a damaged tire.”

Serious tire violations

The Commercial Vehicle Safety Alliance is an organization of state departments of transportation and police that create uniform inspection criteria for the U.S., Canada and Mexico. The most serious CVSA tire violations are:

• Tire flat or with audible air leak;

• Tread and/or sidewall separation;

• Fabric exposed;

• A cut in the sidewall that exposes the ply or belt material;

• Tread depth less than 2⁄32-inch for trailer and drive tires, and 4⁄32-inch for steer tires.

Somewhat less serious violations include:

• Inadequate weight rating;

• Tire underinflated;

• Tire underinflated for the weight being carried;

As these violations indicate, it’s preferable to adjust tire pressure for the load. For example, if running empty for a long distance, it would be better to lower tire pressure slightly to avoid irregular wear in the center of the tread. A chart showing pressure adjustments is available from tire manufacturers.

Pressure adjusted below the maximum but down to a level appropriate for load conditions would not be a violation. On the other hand, if your rig is loaded to 80,000 pounds, the same lower pressure could get you a citation. Even a tire in good condition can lead to a citation if its maximum load rating is less than the weight it is carrying.

Use of an obviously re-grooved tire on the steer axle is another violation. This should rarely be a concern these days, as most owner-operators and small fleets rarely re-groove tires.