With smart operation, you can save money by providing a greater cushion against lube deterioration and engine wear.

Oil might cost more than you realize, especially if you’re not getting maximum use of it. Do a typical change yourself and it still costs about $250 for the oil alone.

Carry extra oil with you, pull the stick daily and keep the crankcase filled to the top. The full volume of oil increases available additives and eases the work done by each quart of oil, thus helping extend the life of an oil change.

Carry extra oil with you, pull the stick daily and keep the crankcase filled to the top. The full volume of oil increases available additives and eases the work done by each quart of oil, thus helping extend the life of an oil change.But assume you extend your change interval from 15,000 miles to 25,000 miles. That extension over the million miles of an engine’s expected lifetime would save a lot. Allowing a modest amount for disposal costs and nothing for downtime or labor, the total savings from adding 10,000 miles to change intervals over 1 million miles would amount to about $7,800.

The typical conservative interval for many owner-operators, 15,000 miles, has been shorter than the standard recommended over-the-road change interval for most engines since the early 1990s. Operators adhere to 15,000 miles because they have heard of many oil-related engine failures at changes longer than that conservative interval.

But oil life is quite flexible. A competent operator can extend that life significantly by paying attention to his maintenance and altering his operation behavior. For example, experts agree that minimizing idling time alone will significantly extend oil life because idling puts more undesirable stuff in the oil than even hard driving. Responsible refiners are willing to stand behind their products even when extending changes. Operating and maintaining your vehicle or vehicles as the experts advise could allow you to extend changes without fear of problems. It could also reduce costs and give you more downtime.

Chevron Lubricants’ Jim Gambill, Delo’s brand manager for the Americas, says the “real issue with extending drains is the maintenance of the vehicle – fuel filters, tires, oil, grease, coolants, etc.”

The critical practices are those that affect the stress on oil. Oil lubricates wear surfaces, but it also cools such critical parts as the pistons, which are not in direct contact with the radiator coolant. When those high temperatures are combined with the oxygen in crankcase air, as well as in the cylinder (for oil sitting on the liner during a down-stroke of the piston), the result is thermal and oxidation-related breakdown. That can quickly destroy oil’s ability to lubricate.

The engine’s primary defense against this heat is the cooling system – especially the oil cooler’s, consisting of copper pipes with coolant on one side and oil on the other that conduct heat into the coolant. Should even a thin layer of scale coat those pipes, oil temperature would rise. The oil cooler can bring temperatures down from about 300 degrees to close to 200 before releasing it into the pan. Without it, oil would decompose quickly during sustained engine operation.

“It’s all about maintaining the optimum operating temperature, which will reduce the thermal stresses and oxidation rate of the oil,” says Rob Banas, commercial vehicle lubricants application engineer with ExxonMobil.

“If the engine temperature is higher, the oil degradation rate will be higher,” says Dan Arcy, Shell Lubricants OEM technical manager. “Glance at the oil temperature gauge every now and then.” Arcy also suggests keeping an eye on the coolant temperature gauge and performing maintenance such as flushing out bugs and debris that have clogged radiator fins to keep engine temperature at the optimum level.

“Other areas of oil stress include allowing impurities such as antifreeze, fuel, or dust in. If you find your coolant level is changing, this should be a red flag” for system problems, says Gambill. An external leak is less problematic than an internal one, where coolant will mix with the oil, react chemically and interfere with the oil’s performance.

Maintaining coolant level maximizes the performance of the radiator by increasing the surface available for heat to be transferred to outside air, Gambill says. You need to keep the system full and properly protected from corrosion by using ELC or with Supplemental Coolant Additives to prevent scale that traps heat.

Arcy also says coolant should not run at too low a temperature. This happens because of a failed thermostat. Cold running causes poor combustion and fuel dilution.

Also keep the oil pan full. “If it’s below the maximum, that accelerates degradation, especially from heat,” Banas says. Keeping the pan full also replenish additives, too.

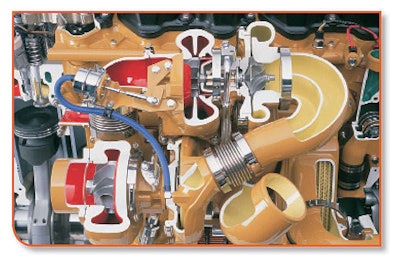

The heat exchanger under the two turbochargers is the oil cooler. Keeping the cooling system clean prevents scale in the oil cooler, too, and this means the oil stays cooler and can resist oxidation much longer.

The heat exchanger under the two turbochargers is the oil cooler. Keeping the cooling system clean prevents scale in the oil cooler, too, and this means the oil stays cooler and can resist oxidation much longer.One of the most critical areas is dirt ingestion. Banas says, “Don’t remove and replace the air cleaner unnecessarily, as that can cause the seals to deteriorate.” Be careful to check the hose connections on the piping that carries the intake air from the air cleaner housing to the suction side of the turbo. A small amount of dust, which is harder than engine metals, can make short work of an engine’s major parts, says Banas.

Don’t be too lax on filter changes, though. Failing to change the air cleaner at recommended intervals can cause it to “become so clogged that it causes increased stress on the oil,” Arcy says. Engines starving for air create more soot.

Adjusting the overheads at recommended intervals will improve engine breathing and injector performance, thus reducing oil soot, while also reducing wear metals in the oil.

Adjusting the overheads at recommended intervals will improve engine breathing and injector performance, thus reducing oil soot, while also reducing wear metals in the oil.Coolant is another critical item that can leak into the oil. Banas says today’s most common source for such leaks is the EGR cooler, which “can cause slow, continuous contamination.” The antifreeze in the coolant reacts with oil, which then oxidizes and becomes abrasive.

Watch for fuel dilution in oil analysis reports, though it’s not common, Arcy says. “The oil’s detergents can handle normal amounts. But a leaking injector is a big problem. Fuel washes right down the cylinder walls.” Most of these troubles are immediately revealed through oil analysis, he notes.

Proper cooling system maintenance means radiator tubes stay free of scale like this. That means the coolant remains at a lower temperature which, in turn, means cooler oil that better resists oxidation and thermal breakdown, and will last longer.

Proper cooling system maintenance means radiator tubes stay free of scale like this. That means the coolant remains at a lower temperature which, in turn, means cooler oil that better resists oxidation and thermal breakdown, and will last longer.Good maintenance of the injection system and the overheads will also help in reducing oil stress. “To extend changes you need to be at the top of your maintenance game,” Banas says. “A lot of the best fleets pay quite a bit of attention to valve adjustment intervals.” He has seen high levels of lead resulting from extra stress on related parts if valves go unadjusted. Poor valve adjustments can also affect engine breathing, and generate excess combustion soot. With unit injectors, the performance of the fuel system can be seriously compromised if overhead adjustments are neglected. Also, Consult your engine dealer as to a good interval when injectors should be pulled and serviced, or replaced with factory-rebuilt units.

Arcy says an injector with a bad spray pattern “can cause fuel to wash down the cylinder walls.” In such a case, using an injector-cleaning additive could help. Gambill says, “Ask your fuel vendor to ensure they filter the fuel. This will help keep fuel injectors clean.” Use fuel filters of the recommended micron rating so internal fuel system parts won’t be scored by tiny dirt particles.

If you extend engine oil changes and don’t grease in between them, Gambill says, use a long-life grease like Delo’s ESI. Greasing is significant because proper lubrication of suspension and steering parts will help keep the truck in alignment and save fuel, which means an easier life for the oil.

3 keys to extended intervals

Use good filtration practices

“Use a filter that will meet all the engine manufacturer’s specifications, and always change it at the recommended interval,” says Shell’s Dan Arcy. “We have no issues with either bypass filters or centrifugal designs. Pulling small contaminants out is always an acceptable practice. Note that Detroit Diesel extended the change interval on the DD15, and filtration technology was a big part of what made this practical.”

BP Castrol’s Corey Taylor, senior development technologist, reminds you to always change filters with the lube. He says some operators skip the filter change to save money, believing the clean oil will take care of any problems. He stresses the need for new filters so additional impurities will be removed.

Involve the filter supplier in considerations of extended drains, says ExxonMobil’s Rob Banas, or do your own investigation. “You might need better capacity (for dirt), or better internal construction.” He says many of ExxonMobil’s customers running extended drains with synthetic lubes use filters with synthetic media, and some can run long drains without an intermediate filter change.

“We do recommend high-quality filters as an important part of routine maintenance,” says Chevron’s Jim Gambill. “We do not recommend the filters that claim to replenish oils or extend oils by chemical additives, as our additive technology is carefully balanced and we don’t want this careful balance compromised.”

Choose right oil grade

ExxonMobil has been promoting long oil change intervals with use of Mobil Delvac 15W-40 synthetic oil for many years, Rob Banas says. “We offer Mobil Delvac 1300 Super, Delvac Elite Blue and Mobil Delvac 1 fully synthetic. Each oil has its design capabilities. Formulations can neutralize and suspend the by-products of combustion almost like a sponge. As you move up the ladder, you have a bigger sponge, either for longer intervals or harder applications.”

Shell offers both “semi-synthetic and fully synthetic engine oils that are extended drain capable,” Dan Arcy says. “However, we always concentrate on the fact that every customer’s operation is unique.” Lubes with a lower initial viscosity grade number like Shell’s T5 10W-30 and T6 10W-40 and 5W-40 are better for cold starting under harsh conditions “because they are not as thick under starting temperature conditions,” he notes. This allows many fleets to curtail idling, which helps extend change intervals.

Chevron’s Jim Gambill says, “If you are looking to extend the life of the product, we are recommending a premium conventional product like Delo 400 LE 15W-40. The viscosity grade works in most places and this oil is proven to deliver outstanding durability…. In very cold climates (operating routinely below 0 F), you may consider something like Chevron Delo 400 LE 10W-30. We recommend Delo 400 Multigrade (CI-4 PLUS) for older vehicles without a DPF.”

BP Castrol’s Corey Taylor says Castrol offers two synthetic blends, Hypuron 15W-40 and Hypuron 10W-30, suitable for extended drain. These have been extensively tested at 50,000 and 70,000-mile intervals, respectively. The company’s Elixion 5W-30 is a full synthetic blend that provides the best protection. “The low levels of oil soot today’s injection systems provide and the use of ultra-low sulfur diesel fuel greatly help to extend the life of engine oil,” Taylor says.

Get routine oil analysis

New engines exhibit levels of contaminants that remain from initial construction of the radiator, oil cooler and EGR cooler. So even when an engine is relatively new, oil analysis is important for proper maintenance, says ExxonMobil’s Rob Banas. Knowing not only the miles on the oil, but the total hours the engine has run, is critical to knowing whether a contaminant is coming in from outside and likely to cause damage.

If you buy oil from an oil supplier and consistently use the same brand, it’s possible the oil refiner will offer free oil analysis. If not, ask your supplier or engine dealer for information on a reputable lab. A good analysis report will cost $30 to $50. Analysis should be performed at every drain if using extended intervals.

15,000-mile changes

25,000-mile changes

Savings

OIL COSTS

$250 for 11 gallons

$250 x 66.6 = $16,650

$250 x 40 = $10,000

$6,650

FILTERS COSTS

$22 for OEM bypass oil filter

$22 x 66.6 = $1,465

40 x $22 = $880

$585

DISPOSAL COSTS

$20 per change

$20 x 66.6 = $1,332

$20 x 40 = $800

$532

TOTAL SAVINGS OF NEARLY $8,000 over the million-mile life cycle of an engine are possible on oil, filter and disposal costs alone when drains are extended from 15,000 miles to 25,000 miles.