“Rotation is not the answer to solving an axle misalignment issue or other mechanical issue,” says Michelin’s Doug Jones.

“Rotation is not the answer to solving an axle misalignment issue or other mechanical issue,” says Michelin’s Doug Jones.Adding tire rotation to your maintenance routine probably sounds like a nuisance. But even when alignment is kept up to snuff, tires do wear unevenly. Add to this the tendency for parts to wear and get out of alignment before you take action, and tire rotation begins to make more sense.

Some experts believe rotation can even out wear and put off the date when tires need to be removed for retreading or replacement because of worn tread. Other tire makers aren’t so quick to recommend it.

“You should rotate only based on actual problems,” says Walt Weller, vice president sales at CMA, maker of Double Coin tires. However, he has seen cases in which some long-haul fleets run steer tires in the drive position for the first 15,000 to 25,000 miles because steers are “prone to irregular wear” in the steer position, but less so after being slightly worn in a drive position. From a wear point of view, this may make sense, but, he says, “Some say the trouble is not worth it. You have to consider the cost of rotating those tires.”

Yokohama’s Pat Keating, senior technical engineer, points out that trailer tires get less benefit from rotation. “Whether the additional mileage is added in a cost-effective way depends on the particulars” of the operation.

“If it is application-specific,” says Ron Gilbert, director of commercial products at Toyo Tire USA, “then tire rotation may be warranted to prolong tire life. Other than this, tire rotation on commercial vehicles causes increased labor cost for little, if any, return on your investment.”

So is it cost-effective to rotate in your application? Consider these points.

Tire wear

“Tires wear at different rates,” says Guy Walenga, Bridgestone/Firestone’s director of engineering. “A good time to rotate is when there’s 3⁄32-5⁄32 difference in wear” between the tire positions. Due to how torque is applied on the front and rear drive axles of a three-axle tractor, “the forward axle doesn’t wear quite as fast because of the way the vehicle pivots,” he adds. “The forward axle doesn’t scrub as much. Something similar happens on the trailer.”

How the load is situated plays a role in uneven wear, too. “Each drive axle should carry half the load,” Walenga says, “but if the fifth wheel is forward or back, the load will not be 100 percent even.”

He adds that one consequence of this uneven wear can be a difference between the rotating speed of the front and rear drive axles. “There is a 3 percent window, and, after that, you get ‘gear fight’ or rotation of the inter-axle differential gears as you cruise down the road,” he says. Rotating your drive tires could conceivably help your inter-axle differential to live longer.

Also, he explains, the left-front steer tire wears faster on a tandem drive tractor. That’s because the steering action is transmitted to the left-front tire directly, while the force travels through more linkage parts and so takes a little more of a rotation of the steering wheel to get to the right-front tire.

CMA’s Weller agrees this wear pattern is common, but he believes it’s often because of bearing problems.

Irregular wear caused by mechanical problems is the other reason to rotate. Correcting the mechanical problem before the tires are rotated, though, is key. Doug Jones, customer engineering support manager for Michelin Americas, puts it this way: “Rotation is not the answer to solving an axle misalignment issue or other mechanical issue that may be impacting the way the vehicle’s tires wear. Irregular wear and/or disproportionate wear rates are good indicators of vehicle and/or mechanical issues.”

Rotation patterns

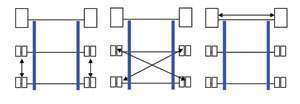

“Steer tires should be rotated from side to side,” says Jones. “Drive tires can be rotated from the front axle to rear axle, side to side across the axle, or crisscrossed.

Trailer tire rotation should be the same as the drive tires. There is no restriction on crisscross rotation, including directional steer tires that have worn 50 percent or more of the original tread. In fact, it is most often beneficial to rotate the tires so that irregularly worn tires are moved to a position where they are turning in a direction opposite the original position.”

Bridgestone/Firestone’s Walenga agrees, saying his company prefers to see the X-pattern used among tandem axles “because you then have a different edge to the outside.” He adds, “When looking at certain types of shoulder wear, after you fix the problem, you may have to break duals apart, moving them in and out.” The shoulder on the outside should no longer show the wear.

Such rotation can also help eliminate heel and toe wear, according to a diagram supplied by Yokohama. Keating says, “Steers should be rotated side-to-side. Drives are best rotated in an X-pattern, in pairs, but where that is impossible or impractical, drive tires can be rotated in pairs, front axle to back axle.”

Walenga adds that some fleets “rotate totally,” which means drives can go back and forth to steers and vice-versa. In this case, you need to use rib tires on all positions. While extra traction may be needed at times, he points out that chains are actually easier on rib tires than on drives that have lugs for aggressive traction, making the use of chains together with rib drive tires a practical way to operate.

To extend mileage on steers, swap them “at about one-fourth of the expected total mileage,” says Goodyear’s Tim Miller, marketing communications manager. For drives, “moving the rearward axle tires to the forward axle and vice versa,” he says, “will even out the wear and help create a situation where all the drive tires are more likely to need replacement at the same time.” As with the steer axle, rotating the tires to the other side of the vehicle “reverses the direction of rotation and helps clean up any irregular wear that may have started.” n

What to look for during rotation

If you uncover irregular wear during rotation, you need to correct the misalignment of steering or front axle wear parts, or of drive or trailer axles, that are causing the problem. Here are a few signs to look for while the tires are off:

• Michelin’s Doug Jones recommends inspecting wheel-end components for wear. Also, “Adjacent dual tires should not differ more than 1/4-inch in diameter (4/32-inch in tread wear). If there is a difference in tread wear, fit the least worn tire in the outside position. Curbing on dual applications often damages tire sidewalls. If so, rotate the wheel and tire to the inner wheel position.”

• Bridgestone/Firestone’s Guy Walenga says to take advantage of the chance to examine the sidewalls of inside duals. “Also, feel the tread to check for irregular wear,” he says. “And check to see if the tire is mounted concentrically. There should be a constant distance between the flange on the wheel and the guide ring on the tire.”

How often should you rotate?

No rotation schedule is so rigid that it’s worth purposely scheduling, says Bridgestone’s Guy Walenga. “We recommend doing it when the wheels are up anyway, and the truck is in for other service,” he says. Here are five takes on rotation frequency:

• At least once during the life of the tread. (Bridgestone’s Guy Walenga)

• At the halfway point of wear-out. (Yokohama’s Pat Keating)

• Only when irregular wear appears. (Michelin’s Doug Jones)

• Once at one-fourth of the total expected mileage, and possibly again at half to three-quarters total mileage. (Goodyear’s Tim Miller)

• At every oil change or every other. (Giti Tire USA’s William Estupinan)

Do it yourself – safely

To rotate tires on your own, don’t cut corners. Get jack stands with ratings more than adequate for each axle, place them on a hard, level surface, and make sure they are squarely under each axle before lowering. If doing just the front or rear axles, chock the wheels still on the ground.

Several experts say that proper mounting includes proper torque of wheel fasteners. Make sure the fasteners and mounting surfaces are clean and threads in good condition — torque fasteners across from one another, 180 degrees apart, going back and forth across the wheel in several stages. Walenga says not to use an air wrench unless precisely calibrated to the proper torque, or unless using a torque stick designed to stop torquing at the right level.

Do final torquing to manufacturer’s specifications with a manual torque wrench. Then, after 50 to 500 miles, retorque in the same way to guarantee a secure mount.

For more detailed advice, Goodyear’s Tim Miller suggests following the Technology and Maintenance Council’s Recommended Practice 237. Doug Jones of Michelin mentions the Michelin Truck Tire Service Manual on the company’s website and the TMC Radial Tire and Disc Wheel Service Manual as references.

Front to back rotation allows drive tires to be replaced as full sets.

X–rotation reduces effects of irregular wear patterns, such as heel and toe wear.

Side to side rotation is best for steer tires.