Not up on zinkdialkyldithiophosphate? No problem.

Grasp these points about engine oil additives and leave chemistry to the engineers.

ConocoPhillips announced a startling claim last year: It had managed to liquefy the exotic metal titanium and dissolve it into diesel engine oils.

Technicians take a field test sample of Kendall Super DXA with liquid titanium, one of the more recent and advanced diesel engine oil additives.

Technicians take a field test sample of Kendall Super DXA with liquid titanium, one of the more recent and advanced diesel engine oil additives.“Our exclusive liquid-titanium additive technology provides a molecular-level shield against wear,” says a company brochure. “It incorporates into metal surfaces to become chemically bonded, particularly in areas of extreme, localized heat.” The result, says Steve Tarbox, director of product management, is an additive that “enhances wear protection, improves corrosion control and reduces oxidation of the oil.”

ConocoPhillips’ development is just one example of oil laboratory breakthroughs over the years. These engineering achievements have led to oils that contain dozens of sometimes exotic anti-wear chemicals that prolong engine life to levels only dreamed of in the past. Here are the key things you need to know about additives.

Regardless of additives, the best oil selection guides are your owner’s manual and oil product labels. “Use the oil recommended by the OEM,” says Chevron Global Lubricants’ West Alexander, products specialist, heavy-duty engine oils. “This ensures that the trucker’s warranty is validated. For all 2007, pre- and post-2007 engines, the primary recommendation is API CJ-4. Oils licensed as CJ-4 have passed nine engine and 14 bench tests. Five of the engine tests are wear tests.”

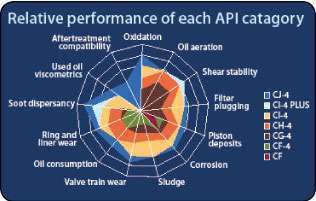

A CJ-4 oil (represented as dark blue), such as Chevron Delo 400, performs better than oils meeting the previous six technical classifications. The farther from the center of the chart the color appears, the stronger that characteristic is.

A CJ-4 oil (represented as dark blue), such as Chevron Delo 400, performs better than oils meeting the previous six technical classifications. The farther from the center of the chart the color appears, the stronger that characteristic is.Each engine manufacturer may have proprietary tests they want the oil to pass other than the basic American Petroleum Institute standard, CJ-4. Check your owner’s manual to get a complete list of needed certifications, and read the label on the oil container to ensure those certifications are included. Most major refiners meet the standards for all diesel engine manufacturers.

ConocoPhillips’ heavy-duty oils with liquid titanium, for example, are API CJ-4 certified and approved by all major engine manufacturers, says Reginald Dias, commercial products director.

Additives must be in correct proportions to work right. No one additive ensures top flight engine oil. “You not only have to protect from mechanical wear, but also from corrosion wear,” insists Dan Arcy, OEM technical manager at Shell Projects and Technology. “You also need to protect the engine from soot, which becomes abrasive if it agglomerates into large enough particles. This means you need a dispersant to encapsulate the tiny soot particles.”

The ideal result is a carefully blended package of ingredients, says Alexander. “The additives must be properly balanced to avoid unintentional adverse effects.”

A Chevron chart lists 11 categories of ingredients. Alexander says it includes an exotic anti-wear component that metal refiners commonly use in their formulations, zinkdialkyldithiophosphate, or ZDDP. The chart says such additives “cause a film to surround metal parts, helping to keep them separated,” similar to what titanium does.

The quantity of an ingredient in oil tells you little about performance. “You can’t judge by content – it’s not that simple,” Arcy says. “For example, zinc and phosphorous are often used for anti-wear protection, yet a 400-PPM (parts per million) cap was put on them with CJ-4. In spite of the reduction, we’ve seen a 38 percent reduction in engine wear with CJ-4.”

One way to evaluate an oil, Arcy says, is to see how well the product performs in field tests. “We’ve tested Rotella T CJ-4 for over 50 million miles in lots of different engines to make sure it will perform well in all applications,” he says. “This includes testing in lots of 2007 engines with advanced EGR (exhaust gas recirculation) and DPFs (diesel particulate filters). The oil has shown excellent wear performance – for example, low iron content.”

Because additives decompose, the only way to replenish them is with a fresh oil change. No matter how effective oil filtration is, it does not replenish depleted additives, Alexander says. “Nor does fine filtration remove contaminants from combustion by-products, fuel dilution, acids, etc.,” he says. “And, extending drains beyond the OEM recommendation could invalidate your equipment warranty.”

As key components of engine oil get depleted or altered, the need for an oil change increases, Dias says. For example, acids produced in the combustion process deplete the oil’s TBN (total base number) or increase its TAN (total acid number). “Under extremely severe conditions, one might see a slow depletion of zinc and phosphorus,” he says. “In such cases, if the analysis indicates that oil has reached condemning limits, it is advisable to change the oil even though the standard drain has not been reached.”

Oil analysis says little directly about additives’ effectiveness. The additive list in an oil analysis report lacks sufficient detail for you to be able to evaluate the additive package, though it has some relevant information.

Alexander says a good report “should have pertinent parameters measured – that is, wear metals, TBN, TAN (total acid number), soot, viscosity, fuel dilution, water/glycol, etc. – and include condemning limits to alert the user of impending problems.” If the report suggests problems, the oil should be changed soon. If the problem persists, the situation should be investigated until resolved.

The key piece of information is the presence of wear metals. “Wear metals will tell you if oil additives are working,” Arcy says. “Also, the report will list contaminants like sodium and potassium that should not be there.”

Using over-the-counter additives is risky. “We discourage people from using oil additives,” Arcy says. “They can disrupt that balance we’ve put into our products.”

This Caterpillar C15 run on Shell Rotella T4 for nearly 670,000 miles shows negligible sludge on the top surface of the cylinder head – a surface that’s very hard to keep free of deposits. Quality oil includes detergent additives that keep combustion byproducts dissolved so they cannot attach themselves to engine parts.

This Caterpillar C15 run on Shell Rotella T4 for nearly 670,000 miles shows negligible sludge on the top surface of the cylinder head – a surface that’s very hard to keep free of deposits. Quality oil includes detergent additives that keep combustion byproducts dissolved so they cannot attach themselves to engine parts.By going with a quality engine oil that has been thoroughly tested, and changing it based on lab analysis or manufacturer guidelines, your engine will be more likely to last a million miles without a breakdown or major repair. And, you can rely on the additives even though you may not fully understand how they work. n