The next Signature truck will start with a Kenworth T660 glider kit, similar to this 2013 model. The goal is to achieve more than 9 mpg when pulling any standard trailer.

The next Signature truck will start with a Kenworth T660 glider kit, similar to this 2013 model. The goal is to achieve more than 9 mpg when pulling any standard trailer.In 2007, I started working on a project that would combine everything I had learned in almost 20 years of testing fuel mileage strategies and technologies – and include a couple of new ideas. I started with a New Freightliner Glider kit and worked with Pittsburgh Power to build the most fuel-efficient pre-emission engine possible. I partnered with Fitzgerald Glider Kits to bring it together in what I called my Signature truck.

The final truck was bought by a small refrigerated fleet that ran between Salt Lake City and the Northwest, usually heavy both ways. The fleet average at the time was 5.7 mpg, and our Signature truck achieved 8.5 mpg in the same operation.

Now I’m working on two new Signature Truck and Trailer concepts. Their goal is to achieve the best fuel mileage and lower maintenance costs and downtime. One combination will be spec’d for general use and should achieve more than 9 miles per gallon. For the other – designed for owner-operators who are willing to step out of the box – we hope to achieve 10 mpg.

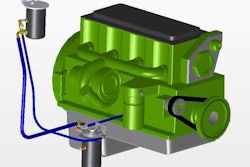

The first will start with a 2013 Kenworth T660 glider kit. We’re building a pre-emission 14-liter 60 series Detroit and putting it in front of an 18-speed single overdrive transmission and a single drive axle with a 2:79 gear ratio.

The idea will be to drive the truck in 17th (direct), the most efficient gear, and still have 18th gear as a true overdrive. The sweet spot for cruising speed will be 55-60 mph in 17th and 60-68 mph in 18th, when necessary or light/empty. The axle configuration is unique; we’ll have a 23,000-pound locking rear differential and a forward liftable axle with trailer tires for even lower rolling resistance on that axle.

The key three areas for fuel efficiency are:

REDUCING AERODYNAMIC DRAG: Starting with the T660 gives us a great platform for aerodynamics, but we’re going to add some proven aero devices as well as some promising items. We’ll add Airtabs to the rear edge of the sleeper extensions, which we’ve used for years, and we’ll be testing the FlowBelow Aerokit to improve airflow in and around the axles and wheel ends.

IMPROVING ENGINE EFFICIENCY: We’re employing several technologies here:

**Fleet Air Filters, which are lifetime foam washable filter elements that improve airflow into the engine by as much as 25 percent.

**Custom-programming the ECM for maximum fuel mileage and adding the FASS Fuel System for improved fuel flow and to remove all air from the fuel supply.

**OPS Eco-Pur oil bypass system and a 5w30 fully synthetic oil for lower mechanical resistance.

**Custom-built exhaust system, starting with a Pittsburgh Power ported and jet-hot coated exhaust manifold to improve airflow out of the engine. This – combined with a larger turbo housing, turbo and exhaust wrap, and a high-flow muffler – will give the least amount of backpressure possible.

**Evans lifetime waterless coolant, allowing slightly higher engine operating temperature to improve engine efficiency.

DECREASING ROLLING AND MECHANICAL RESISTANCE:

**To reduce mechanical drag in the driveline, we’ll install MicroBlue-treated wheel bearings in all positions and use the lightest-weight gear oils possible. The 6×2 configuration also lowers driveline resistance.

**Rolling resistance will be lowered by using Michelin XZA3 Evertread for the steer axle, the new X Line Energy D wide single for the drive axle and the X-One XTA trailer tire for the forward liftable axle.

**Aligning the system using MD Alignment methods and balancing all wheel positions with Counteract Balancing Beads to further lower rolling resistance.

**Lifetime high-performance RoadKing Shocks.

Next month I’ll cover the design of the trailer and new ideas for axle configurations.