Last month I discussed how oil doesn’t wear out but needs changing only because it becomes too contaminated to do its job. Changing oil at an arbitrary mileage points to only two scenarios, both bad: If your oil is dirty, you’ve already damaged your engine, and if it’s not dirty, you are throwing away clean oil.

Oil analysis gives you the information to handle drain intervals more sensibly and confidently. What’s even better is that bypass filtration adds another dimension to save money and downtime.

Factory filters allow full oil flow to maintain proper oil pressure. Because of that, the filter cannot trap smaller particles below 30 microns. Many contaminants are much smaller, even less than 5 microns. Because full-flow filters can’t capture those contaminants, the oil will degrade, requiring frequent drains.

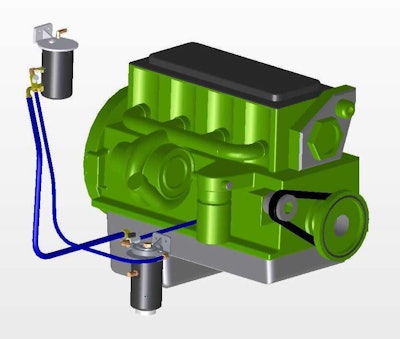

The Eco-Pur from Oil Purification Systems is an example of a bypass product that filters both solid and liquid contaminants.

The Eco-Pur from Oil Purification Systems is an example of a bypass product that filters both solid and liquid contaminants.The best bypass filters can filter down to 3 microns or less. I recommend using a bypass filtration system that has a heating element, enabling it to eliminate both solid and liquid contaminants. Fuel can end up in your crankcase due to high idle time or a problem in the fuel system such as those seen in fuel pumps, injectors or injector seals. Fuel in the crankcase lowers the oil’s viscosity and interferes with its ability to protect engine components. Even small amounts of fuel in the oil can cause bearing wear as well as excessive wear on cylinder liners, pistons and rings.

Another liquid contaminant is coolant intrusion from blown head gaskets, a cracked head, leaking exhaust gas recirculation (EGR) coolers, etc. Coolant strips the zinc from the oil, leading to higher wear metals and decreased engine life.

High soot is caused by EGR that brings the exhaust gas back into the cylinder, as well as by diesel particulate filters that create high amounts of backpressure. A good bypass filtration system will help keep soot levels lower.

Instead of changing oil and filters at some mileage point, consider installing a bypass filtration system and using it with an oil analysis program to know exactly what is going on with your oil.

The numbers spell it out. Most systems can be bought and installed for less than $1,000. That might sound like a lot, but you easily can return that investment in less than a year.

If you change oil every 15,000 miles, you are spending about $2,400 a year and not protecting your engine as well as possible. You also have no idea about the condition of your oil, assuming you’re not doing analysis.

|

STEPPING UP TO SYNTHETIC **Better fuel economy. |

With a bypass system, you would go 25,000 miles, change the bypass filters and take an oil sample; the results would dictate if you needed to change your oil. Using that system, most newer engines are able to go 150,000 to 200,000 miles without an oil change. Older engines with less complicated emissions systems can go as far as 400,000 miles. I have owned trucks that went more than a million miles with only four oil changes.

The filter and oil sample for most bypass systems will cost $50 to $75, and that includes the sample results. That lowers your annual cost to less than $300 – a savings of more than $2,000 a year.

The bottom line is with this kind of system, you’re spending much less money while protecting your engine and the environment. That’s a no-brainer.

If you’d like to know which bypass filter I recommend and where to get a quality oil analysis, write me at [email protected].