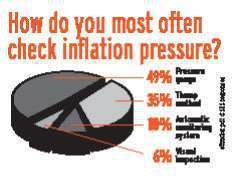

Checking your tires’ pressure regularly is like exercising – you know you should do it, but it’s easy to put it off.

Tire professionals say there’s a huge payoff for sticking with this routine. It will head off irregular wear that can reduce tire mileage, preserve the casing for retreading and enhance fuel economy.

The safety aspect of proper inflation is more important than ever. Not only does it help avoid catastrophic tire failure, it’s also a sensitive item with the Compliance, Safety, Accountability program. Under CSA, a tire violation carries among the highest severity weightings, adversely affecting your own or your leasing carrier’s score to a great degree. Tires are among the easiest pieces of your equipment for inspectors to check, too, says Guy Walenga, director of commercial products engineering and technology at Bridgestone/Firestone.

What is the proper pressure?

Ideal pressure varies with the weight you’re hauling. If you’re accustomed to hauling 80,000 pounds most of the time and you run few empty miles, choose pressure for the heaviest loads.

Many operators follow a standard of 100 psi in all tires. That may be adequate for steers, but it will make the drive and trailer tires overinflated by as much as 15 psi with a normal configuration of two tractor axles and two trailer axles, says Walt Weller, sales vice president at CMA, maker of Double Coin tires. Overinflation is “the lesser of two evils compared to underinflation,” he says.

50% Tires within 5 psi of the recommended pressure.

Walenga recommends 110 psi for steers on a truck with a setback axle and a 12,000-lb. steer axle rating. “At 105, you’re technically underinflated,” he says. “For the steer axle you don’t have any leeway. You need the maximum pressure to make sure you’re carrying 12,000 pounds” effectively.

20psi One out of 14 tires underinflated by at least that amount.

Under a full load, drive and trailer tires could be adequately inflated to about 75 psi, says Roger Stansbie, a director of truck tire engineering at Continental Tires, but most carriers and operators keep pressures much higher than that for better traction and to avoid letting pressures go too low.

20% Dual-tire assemblies with pressures differing more than 5 psi.

Also, inflate both tires in dual pairs in the drive and trailer positions at the same pressure. To facilitate checking the pressure for duals, make sure the tires are mounted so the valve stem is at the 12 o’clock position on one of the tires and at 6 o’clock on the other, so as not to block access to the inner stem, Walenga says. If you don’t have that alignment, you’re less likely to make the effort to check the inside tire for pressure. “Slowly the inside tire will lose air – a pound or two every month,” he says, “and soon you will have irregular wear.”

All tire manufacturers publish load/inflation tables and booklets with recommended inflation pressure by load. Another source is the Tire and Rim Association’s annual guidebook – visit www.us-tra.org to order.

How do you accurately check pressure?

The recommended method for checking inflation pressure is to use an accurate tire gauge. Keep it from getting banged around in your toolbox and losing its accuracy. Periodically have the gauge calibrated at a truck stop or tire shop, advises Doug Jones, a customer engineering support manager for Michelin.

Veteran operators may use a ball bat, billy club or tire iron to thump their tires, but you can’t reliably discern how much air is in a tire with that method, says Tim Miller, Goodyear’s marketing communications manager.

Kurt Grote, an owner-operator leased to John Christner Trucking, says he used a gauge daily before he switched to an automatic monitoring system three years ago. He was checking for 120 psi in his steers and 100 psi in his drives, regardless of the load. He says it took about five minutes each day. Today, even with the monitoring system, he still uses a gauge weekly to check pressures.

How often should you check?

Jones recommends checking pressure as part of your daily vehicle inspection. He notes that air pressure checks are part of pre- and post-trip inspections, as required by the Federal Motor Carrier Safety Administration. Also have pressures checked during preventive maintenance and other repair shop visits.

Tire professionals recommend checking inflation pressure with a calibrated tire gauge instead of thumping tires.

Checking pressure before you begin your route each day will give you a cold tire reading, which is preferred. Walenga says pressure will increase 10 percent to 15 percent once tires heat up from highway driving, a fact good to keep in mind if you’re in the habit of checking pressure when you stop for fueling.

“With CSA, I think that’s going to help to get people to check pressures and be more responsive to tire issues since tires are one of the things that will get the most [CSA] markups,” he says.

Should you adjust pressure for the load?

Adjusting pressure for every load variation would be ideal, but it’s not realistic, Walenga says. By inflating to your maximum loads, you will avoid the risk of being underinflated. All the same, he adds, “if you run lighter, you could go to a chart that shows different air pressures for different loads.”

Miller notes that “if you want tires to give the best performance, especially for wear and traction, you could adjust for every load.” He points to the many logging trucks outfitted with central inflation systems that adjust pressure to weight and terrain, whether off-road or on-highway.

Jones says to maximize tire design and engineering, you should match the pressure with the load. If they aren’t matched, tires can wear prematurely or fail, and fuel economy could fall. “If the load is too much for the air pressure, you’re going to have a problem,” he says. “If air pressure isn’t sufficient to carry a load, you’re also going to run into a problem.”

Operators who run less-than-truckload or long haul with multiple stops might consider inflating less than maximum pressures in all tires except the steers, but still stay above minimum recommended pressures, Stansbie says. Steers need maximum pressure to exert side force whenever the tire is turned. “If you have an underinflated steer tire, you need to turn the steering wheel a lot more on a curve than with a fully inflated tire,” he says.

Overinflated or underinflated?

Overinflated tires may produce a rougher ride and handling. Jones says they are more susceptible to hydroplaning on wet surfaces. They also are more vulnerable to puncture from road debris because of their stiffness.

But don’t be too quick to bleed air from a hot tire that’s overinflated from pressure buildup, Miller says, or from a cold tire that’s running in higher ambient temperatures in summer. Heat increases inflation pressures from their cold starting levels, so deflating hot tires means you run the risk of being underinflated when the tire cools.

When a tire is underinflated, it tends to flex more, building up heat. The sidewalls begin to stress under the pressure and cables fatigue. “You can get what we call a zipper rupture,” Jones says, “when one of the cables will give and other cables will follow and push out the sidewall.”

He compares it to bending a coat hanger, which will never return to its original shape. “If a tire is severely overloaded, failure could happen in a matter of a few miles,” he says.

Occupational Safety and Health Administration regulations specify that a tire with less than 80 percent of target inflation pressure should be treated as a flat. It should be removed, examined and reinflated, if possible, in a cage to protect against an explosion, Jones says.

Walenga advises against reinflating an underinflated tire to the proper pressure and driving. “It’s a possible zipper rupture waiting to happen,” he says. Even if the tire is 10 psi below its target pressure, you should examine the tire for faults before you inflate.

Miller says a badly underinflated tire probably isn’t a retread candidate. Overdeflection, or extra heat in the tire, will show up as discoloration in the liner or even damage to the cables or cords. It could also overload the tire next to it in a dual pair and eventually cause damage to that tire as well.

Stansbie says a Continental truck stop survey found that 30 percent of tractor tires and 40 percent of trailer tires were inflated below minimum recommended levels. “The tires on average were 12 percent underinflated,” he says. “We calculated on an 80,000-lb. rig, running 120,000 miles a year, based on $4.17 a gallon and 5.5 mpg, you’re losing $1,400 a year.”

Automatic pressure monitoring

Kurt Grote moved to an automatic inflation monitoring system when he moved to using wide single tires in place of his dual drives because he wanted to know if he was in danger of tire failure.

“That would give me time to shut down on the shoulder or a safe place to get the work done,” Grote says. “The system I have now has already saved me two tires and two rims. That’s around $2,500.”

When owner-operator Kurt Grote switched to wide single tires, he installed an automatic monitoring system to do the job.

Grote bought his first automatic system in 2008 when he switched to super single tires. Last June he updated to a Doran 360 HD system for $750. A screen in his cab allows him to monitor his tires, which he checks each morning. The system alerts him if inflation pressure drops 12 percent below a set level in any of his tractor tires.

“I urge drivers with singles [to get a pressure monitoring system], because once they go down, you’re down,” he says.

Jim Samocki, general manager of Doran Manufacturing, says the wireless system includes the in-cab monitor and sensors mounted on the tire valve stems. The operator programs the desired pressure for each tire. The system provides audible and visual alerts if the pressure drops 12.5 percent or 25 percent below the set pressure. In addition, a FastLeak alert is triggered when the pressure falls 2.8 psi in less than 12 seconds, he says.

The system can be installed in less than an hour, including connecting the display power wire into a 12-volt power source or hard-wiring into the truck’s electrical system, Samocki says. The sensors are projected to have a 3- to 5-year battery life and can be transferred when you change tires.

PressurePro, a competing system that has been in the market for 12 years, also provides 12.5 percent and 25 percent low-pressure alerts, along with two high-pressure alerts to warn of high temperatures, says Duane Sprague, president of L&S Safety Solutions, a PressurePro distributor. Sensors attached to valve stems automatically send alert settings every time tire pressures are changed, without requiring the operator to program the pressures. Sensors have a 7-year battery life. The cost is $743 for a 10-wheel tractor, including sensors, monitor and external antenna.