Careful DPF maintenance will boost both your uptime and bottom line.

When the diesel particulate filter was introduced with the change to 2007 engine technology, manufacturers were careful to explain the importance of cleaning the filter to remove engine oil ash that accumulates.

Visible soot is easily dislodged, but going into small passages to clean out soot, especially if it’s gooey or hardened, is much more difficult.

Visible soot is easily dislodged, but going into small passages to clean out soot, especially if it’s gooey or hardened, is much more difficult.However, because carbon can be sticky stuff, there’s another DPF maintenance concern. A small amount of carbon may adhere tightly to the DPF’s ceramic walls, forming gooey or even hard deposits, especially if the engine is not operating properly. It’s similar to what happens as spark plugs in a car deteriorate and need to be replaced.

Cleaning this stuff out can be far more challenging than getting rid of the relatively powdery ash. Inadequate cleaning can compromise the unit’s life and warranty, while thorough cleaning may result in better fuel economy and more miles before cleaning needs to be repeated.

Due to the DPF’s complicated construction and the tendency of carbon to bond to ceramics, cleaning the DPF is a science. Even cleaning out the ash, which stays fairly loose, is a tedious job because it’s distributed through nearly all the passages.

Because getting a DPF back to 100 percent of its original performance level is so complex, picking the right service provider and ensuring use of the right equipment are critical.

When to clean

The system has a microprocessor that provides warning of troubles or the need for routine maintenance. “The warning lights recognize the miles, fuel used and other factors,” says Detroit Diesel Engine and Component Marketing Manager Brad Williamson. The processor knows the difference between a gradual accumulation of ash and a rapid buildup of soot due to low exhaust temperatures.

In the Cummins Filtration DPF, the diesel oxidation catalyst is on the left, and the particulate filter is at the center. While the catalyst does not need routine maintenance, it can be harmed by engine problems such as head gasket leaks.

In the Cummins Filtration DPF, the diesel oxidation catalyst is on the left, and the particulate filter is at the center. While the catalyst does not need routine maintenance, it can be harmed by engine problems such as head gasket leaks.Yet most experts believe you shouldn’t wait for a warning light. They advise a more pro-active approach that anticipates the need for cleaning.

“Dashboard warning lights simply indicate when regeneration is required or occurring,” says Paccar Parts Business Development Manager Larry White, “but they are not an indicator of a required DPF cleaning.” In addition to observing the published service interval, other ways to determine it’s time to clean should also be considered: “A driver needs to also pay attention to an increase in the frequency of active regeneration cycles, loss of power, and a decrease in fuel economy,” he says.

Bob Giguere, a product support manager at Inland Power Group of the WheelTime Network, recommends first determining your duty cycle. “Is the truck used for long-haul, regional or local pickup and delivery service?” he says. “Does it idle eight hours a day? Each situation needs to be treated differently. Under ideal conditions, in over-the-road service, you can go 300,000 miles, but with a lot of idling, or local service, you’ll see shorter intervals.” He believes it is often practical to follow manufacturers’ recommended intervals for DPFs operated under favorable conditions.

What’s favorable? Giguere says the amount of oil consumed and engine hours are key factors. A primary reason for clogging is ash from oil the engine consumes, and idling engines use more oil because the piston rings work less effectively. They depend in part on the higher cylinder pressures created under load to work at their best. Idling also means poor combustion of fuel and more soot, potentially fouling the DPF.

Navistar Customer Service Organization rep Mark Ehlers says you should use the interval “published in the operation and maintenance manuals. It’s a best practice to recheck in later manuals, with the dealer, or via the engine maker’s website to see if they have published an update later.”

He notes that intervals vary with oil type. “Our 2007 interval when running CI-4 oil is 200,000 miles, 22 months, or 4,500 hours, while with CJ-4 it is 250,000 miles, 30 months, 6,000 hours. The difference is that a lot of the ash was taken out of CJ-4.

Volvo Powertrain Marketing Manager Ed Saxman says his company recommends cleaning the DPF at 250,000 miles or 4,500 hours, whichever comes first. “The DPF is large enough that, with proper maintenance, there is not a significant performance difference between a new filter and a dirty filter,” he says, adding that you’re only likely to notice a difference “if the filter becomes full of ash.”

The recommended cleaning interval for Detroit Diesel engines is between 300,000 and 400,000 miles for most applications, notes Williamson. “The other way to determine this is to remove the filter and use the Detroit Diesel service tool to check the capacity.”

Where and how to clean

Owners “should thoroughly familiarize themselves with what the manufacturer of the DPF recommends among the many different cleaning methods,” Giguere says. “Cleaning methods include compressed air or heat or a combination of both. But, some filters may be sensitive to high temperature or pressure.”

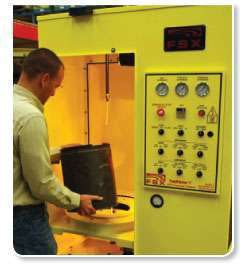

This FSX machine is used by Navistar and Paccar Parts in cleaning DPFs.

This FSX machine is used by Navistar and Paccar Parts in cleaning DPFs.One sure approach is taking advantage of a technology the manufacturer has developed. Giguere notes Detroit Diesel’s method of treating the interior surfaces with a liquid is “substantially different from the methods used by other manufacturers. By applying a liquid, Detroit feels they can clean the filter to a higher level.”

Cleaning is done at Detroit’s network of remanufacturing centers, which are outfitted to do liquid and air cleaning. Williamson recommends simply utilizing the reman exchange program to swap a dirty DPF for a newly cleaned one.

Detroit Diesel’s website reveals its DPF is constructed of a material designed to tolerate the water-based cleaning process. It also says that its reman units are covered by a one-year warranty with no limit on miles, and that the change interval for a DPF cleaned with their process has the same recommended service interval as a new one.

Volvo also encourages owner-operators to exchange with a factory-reman filter. “Cleaning a DPF involves more than just using an industrial vacuum cleaner to remove soot,” says Saxman. “Remanufactured filters customers receive through the Volvo exchange program have been ultrasonically inspected to detect any anomalies before undergoing our thorough cleaning process.”

Another reason to be aware of manufacturer recommendations: Maintaining your warranty. “If you have the unit cleaned using an unapproved method, it could alter your warranty,” says Pacific Power Products Emissions Business Unit Manager Gary Parsons.

In choosing a shop to do the work, says Parsons, look for a cleaning process “that is documented step by step. They should be keeping records that will verify that each step of the process was completed on each filter you send in for cleaning. There should be a check sheet.”

Ehlers stresses the value of a shop’s experience doing the job. “International partnered with FSX to develop its cleaning process. It gives by far the most thorough cleaning, from data I’ve seen. The filter is baked first for 4 to 24 hours, depending on the design, to loosen the carbon. It works like a self-cleaning oven, and this turns gooey stuff that is hard to clean off into a powder. We also have the ability to flow-test the unit after cleaning to make sure it has been thoroughly restored to original condition. Ask the facility whether or not, if the unit clogs after six months, they will stand behind it.”

Paccar also utilizes the FSX cleaning process, says White. “We recommend the use of a machine that employs a visual cleaning process over one that uses a pulse cleaning process. Pulse cleaning assumes that all cells are plugged equally and results in inconsistent and incomplete cleaning. A DPF’s outside cells tend to gather more ash buildup than the cells near the center of the filter.”

He adds that any shop should have testing capability as well. Without it, “it’s impossible for the technician to know how clean the filter is after cleaning.” FSX utilizes an airflow tester called the TrapTester7.

Maintenance for optimum DPF cleaning intervals

A DPF can work like a canary in a mine, says Myron Birschbach, vice president of aftermarket sales for Inland Power Group. “This form of aftertreatment can be a very good early warning device that can tell you you have an operating issue with an engine.”

Frequent clogging can warn of a problem with an injector, an air handling system or oil consumption. Such early notice could help reduce the cost of repairs and potential downtime.

The other side of the coin is that engine maintenance will pay larger dividends than in the past by extending DPF cleaning intervals. Proper maintenance includes:

• Regular oil changes to keep wear and oil consumption under control.

• Ideally, use of CJ-4 oil to extend the cleaning interval.

• Minimized idling. The resulting high oil consumption significantly increases ash accumulation.

Navistar’s Mark Ehlers says a static regeneration inhibition switch on vehicles with a power takeoff allows you to stop regeneration in certain conditions because so much heat is created during regeneration that it could risk fire or other damage, especially indoors. The risk is higher with horizontal DPFs. But don’t inhibit regeneration unless there’s a good reason.

On Internationals, one light advises to try to get the truck up to speed to clear out accumulated soot. Another advises to stop and do a parked regeneration. To understand what these mean, read the owner’s manual or visit the manufacturer’s website.

In parked regeneration, the engine raises the exhaust temperature. This does a better job of cleaning out soot than can occur under even favorable driving conditions. Following the directions is in large part about letting the unit regenerate itself as soon as indicated and as often as you can to decrease the chance the unit will need cleaning prematurely.

Ehlers says to watch for head gasket leaks that could allow coolant into the exhaust stream. Just five gallons could cover the platinum oxidation catalyst designed to accelerate regeneration, leaving the unit subject to frequent clogging. Clean the hydrocarbon injector as recommended to preserve the spray pattern.

And repair any exhaust leaks right away. Any loss of heat in the system inhibits the unit’s natural ability to burn off soot.

Volvo’s Ed Saxman warns against waiting too long to clean a Volvo DPF even though “there may not be a tremendous fall-off in performance. Cracks can form in the ceramic as a result of excessively frequent active regenerations,” which increase the temperature of the filter up to 1,100 degrees F.