CNG refueling is simple, requiring no protective clothing or special gear.

CNG refueling is simple, requiring no protective clothing or special gear.You’re heard the arguments against using natural gas in trucking. Range limitations, as well as weight and fuel tank configuration, are the primary issues.

Yet the industry as a whole seems to have decided that the advantages of using natural gas outweigh any problems. The United States has the largest natural gas reserves in the world, making the fuel cheaper for North American operators, as well as a more secure energy source given today’s geopolitical realities. Even better, natural gas has been used in industrial applications and, to a limited degree, automotive applications for decades. It’s a proven technology, and one that industry leader Westport Innovations feels soon will find its way into a wide variety of transportation niches – including marine and rail.

While switching to natural gas requires changes in infrastructure, maintenance and operations, progressive heavy-duty fleets are proving daily that these adjustments aren’t earth-shattering. And once drivers, managers and technicians have made the switch, they’re finding natural gas to be a good fit for their bottom lines.

Both compressed and liquefied natural gas have their pros and cons, and each has its place in the market. It’s not expected that one will “win out” over the other.

Truck makers feel that heavy-duty natural gas trucks eventually could make up 15 to 20 percent of the Class 8 market in the United States, and even more in medium-duty fleets. There’s a fair chance you’ll drive one of them unless you’re planning to retire in the near future. Here’s a primer to get you ready:

COSTS

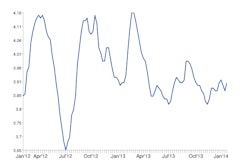

- Natural gas sells for about half the cost of diesel fuel. But suppliers feel that if it were taxed on par with diesel or gasoline, that price could drop more.

- Given the high cost of natural gas equipment, high-mileage use – most manufacturers say at least 80,000 miles a year – is necessary to pay for it. Assuming fuel purchases at half the price of diesel, expect to see a return on your investment in 24 to 30 months followed by significant bottom-line savings. If the spread between gas prices and diesel prices increases, the return would be quicker and the savings greater.

ENGINES

- Natural gas engines do not care about the type of fuel once it gets to the combustion chamber. The main differences involve fueling, fuel storage and how the fuel gets to the combustion chamber.

- Although there is a slight drop-off in power, thanks to natural gas’s lower BTU content, performance in a Class 8 truck is comparable to diesel power. That’s particularly true when the natural gas engine is mated with an automatic or automated transmission.

- There are three main types of natural gas engines: spark-ignited, compression-ignited and pilot-injection, which uses a constant-rate shot of diesel fuel to initiate combustion.

VEHICLE ACCOMMODATION

- Because of the systems required to pressurize CNG to 3,600 psi for storage at stations and on vehicles, CNG tanks are more costly and take up more space on frame rails than LNG tanks.

- There is no “range penalty” associated with one fuel over the other. The biggest issue facing fleets is the additional weight of a CNG chassis – which is about 2,000 pounds heavier full of fuel – as well as the additional amount of space required to provide tank capacity to meet LNG range requirements.

- CNG fuel tanks can be expensive. Fleets reportedly have spent up to $20,000 to replace a tank damaged in an accident.

FUELING

- CNG refueling is relatively easy: You hook a gas line to the truck and pump. Although “fast fill” CNG configurations are available, most CNG fleets choose to “slow fill” trucks connected to a CNG grid overnight.

- LNG is frozen to -265 degrees Fahrenheit to liquefy it, saving storage space and weight. Because of LNG’s cold handling temperature, protective gear must be worn when fueling LNG vehicles.

- If an LNG vehicle is parked with a full tank of fuel, the fuel will warm and begin to vent in four to five days. In another five days, the fuel will dissipate. This, experts caution, literally is allowing money to evaporate into thin air. If a vehicle is operated and fueled daily, it will not vent under normal circumstances.

- Because cold LNG is denser than warm LNG, you can get more cold LNG into a fuel tank than warm LNG. This reduces the chance of venting fuel while increasing both hold time in the tank and potential vehicle range by up to 20 percent.