I spoke to Mike Riegel with the Blue Ink Technology (BIT) company this morning about a new onboard scale they’re offering as part of their monthly “Full Service” subscriber system for add-on features to their base electronic log product. BIT, regular readers will recall, is one of the very few ELDs that is available as freeware, i.e. you purchase the ECM plug-in and there is no monthly subscription fee for the base product; smartphone apps and online portals that interface with the device that plugs into the ECM come free of charge for base ELD users.

Blue Ink Tech, though, has been expanding their utilities under a $30/monthly add-on service. Among other features, it enables partially automated IFTA data collection and reporting, a tire-pressure monitoring system (TPMS) with some wireless-enabled sensors (which we wrote about when it was relased here) and, now, the Air Scale onboard scales system, capable of being set up for all needed axles. Like the TPMS, Air Scale’s sensors (just one required for each tandem pair or steer axle at $100 in base cost per sensor) communicate wirelessly and update weight estimates in near real-time, Riegel says. The new product is of a piece with the company’s mission, he says, to help combat by elimination a variety of the “interruptions that drivers face on a daily basis” that suck time and money from their businesses.

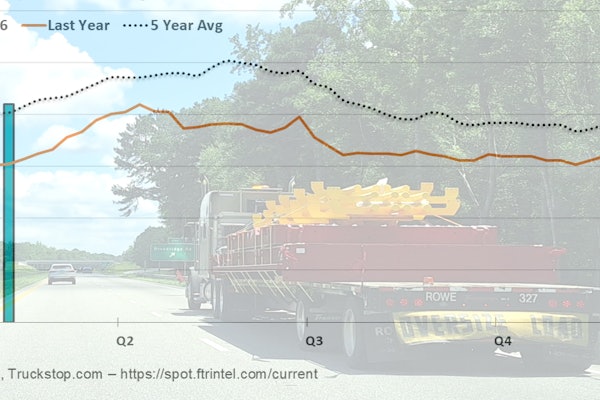

One of those, of course, is getting overloaded at a shipper only to find out some 30 miles down the road at the nearest scale and have to backtrack or, worse, run the risk of fines if you don’t waste more time dodging scales on back roads.

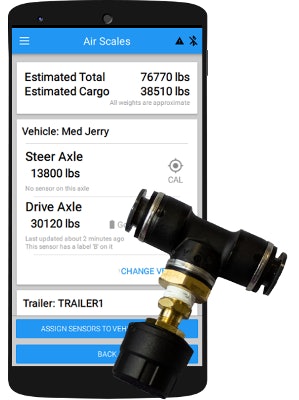

The Air Scale sensors, Riegel says, come with a “very simple install,” with the sensors placed at each air control valve with a push-to-connect Tee fitting, as shown on a drive axle here.

The Air Scale sensors, Riegel says, come with a “very simple install,” with the sensors placed at each air control valve with a push-to-connect Tee fitting, as shown on a drive axle here.With Air Scale operational, “as the truck’s being loaded, drivers are watching the weight go up” on their smartphone from the cab. Drivers will “be able to accurately tell as soon as they’re done” if they’re in the within the safe margin of error for a properly calibrated system — 500-700 pounds, Riegel says. Calibration is a matter of getting a good empty weight, then confirmation of a loaded weight on a scale, and some actions taken within the controlling application.

Batteries in the sensors last for about a year, and the driver application “delivers alerts for low battery” ahead of it needing change.

Batteries in the sensors last for about a year, and the driver application “delivers alerts for low battery” ahead of it needing change.If you’re constantly using different trailers in a single-company drop-hook operation, furthermore, the system can be set up for the driver to easily shift between trailers to see weight readouts with proper calibration just by hooking as normal and entering the trailer number into the app.

Find more information on the new system via this link to Blue Ink Tech’s site. The West Virginia-based company only sells to users directly, Riegel says, and always proceeds with delivery only after double-checking the correct system is ordered to fit an operator’s needs.