Owner-operator Zach Beadle -- find more pictures from the photo shoot at the Thigpen Ranch from 2016 at this link.

Owner-operator Zach Beadle -- find more pictures from the photo shoot at the Thigpen Ranch from 2016 at this link.

Regular readers will no doubt recollect the hardworking 1976 Peterbilt cabover of owner-operator Zach Beadle, hauling cattle and hay and much else besides from a Texas home base. It's pictured above from our shoot with Beadle attendant to the early-2016 "Building the customer base" feature series about Beadle's and others' pursuit of shipper-direct freight in various niche specialties.

But do you recall his second rig? I wrote about it a couple years ago, too, also a 1976 model he purchased with the intent of securing the future of his long-running rig. For any owner of an older-model truck who's got enough mechanical know-how for most jobs, his move to purchase the "parts truck" is one that's easily imitated, provided you can find the right rig for the right price.

Long-term, it could save you both money and time hunting down replacement parts and, as Beadle noted in a message to me from early in 2020 after crossing a scale, passing inspection. He'd recently put work into "rear suspension bushings, front spring shackles and the various maintenance issues that I do take care of," not to mention money into other issues he doesn't, and it "paid off," he said. "Furthermore, the sense of pride in the hard work maintaining my truck is worth every penny. I’m riding down the highway with the memory of passing four or five other trucks on the side that are 20-40 years newer than mine." On the side meaning, of course, that Beadle's hauled on by and "they're still dealing with the law in the aftermath of a failed inspection."

Beadle's investment in the parts truck, further, paid off recently with a few sizable jobs he took on. Run through them -- and more -- via the images below:

The first of the projects was to rebuild the fifth-wheel frame, given light rusting issues, Beadle said, utilizing pieces from the parts truck. Pictured here is Beadle's "go-to guy in metallurgy," aka his eldest son, a welder by trade.

The first of the projects was to rebuild the fifth-wheel frame, given light rusting issues, Beadle said, utilizing pieces from the parts truck. Pictured here is Beadle's "go-to guy in metallurgy," aka his eldest son, a welder by trade.

The truck's frame under the fifth wheel's on Beadle's runner had "suffered slight rust pitting but nothing alarming, especially after 44 years," he said. It wasn't disablling, either, so Beadle and his son, a welder by trade, cleaned and treated the rust with the Ospho product, using wire wheels as well. "We painted the frame before installing the new fifth wheel frame."

The truck's frame under the fifth wheel's on Beadle's runner had "suffered slight rust pitting but nothing alarming, especially after 44 years," he said. It wasn't disablling, either, so Beadle and his son, a welder by trade, cleaned and treated the rust with the Ospho product, using wire wheels as well. "We painted the frame before installing the new fifth wheel frame."

Here's the new fifth-wheel frame going on.

Here's the new fifth-wheel frame going on.

The second project, almost done when I spoke to Beadle in December, was replacement of stack supports on his unit with these new powder-coated from the parts truck he purchased two years ago. He's also added the new stabilizer light bar between them, with a "center pivot air line hanger in the center of the light bar for the trailer hoses and wires." As he put it then, "I want to get away from the pogo stick."

The second project, almost done when I spoke to Beadle in December, was replacement of stack supports on his unit with these new powder-coated from the parts truck he purchased two years ago. He's also added the new stabilizer light bar between them, with a "center pivot air line hanger in the center of the light bar for the trailer hoses and wires." As he put it then, "I want to get away from the pogo stick."

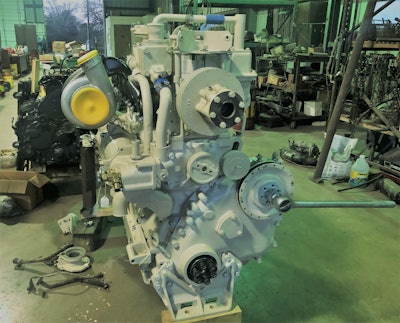

And that big investment he mentioned early last year, in work he doesn't typically do himself? It was a reference to another project he was set to finish right after Christmas -- a replacement of his engine with the one pictured below, what had been an irrigation motor in its first life. It's a Cummins Big Cam block whose previous owner had purchased for his own spare parts engine, employing a tack similar to Beadle's with his donor-parts truck -- which initially supplied the transmission and rear end in his runner today (in addition to the parts shown above, among others).

"My mechanic has been quoted as saying that this is a restoration project as much as it is a motor rebuild," Beadle says of the engine. "It was a running engine when removed from the well it pumped water out of" some time ago. "It was in the possession of the guy I haul hay for. He acquired it as a parts engine and some years later asked if I wanted parts off of it, that he was going to scrap it. I looked at it and saw that all he had taken off of it was a rocker box, fuel pump, one injector and the starter. I told him I'd take it. My plans were to tear it down and assess its foundational condition and possibly rebuild it."

The unit had never been overhauled, and his machine shop reported that foundational components were more or less like new. "No machine work was required for the block, crank, or connecting rods," Beadle said. "The heads were completely rebuilt with all new valves, guides and seals. Rocker boxes and cam followers were rebuilt with all new parts – new cam, and all new bearings."

The parts Pete he bought came in handy again, too. "One of the rocker boxes that was removed prior was replaced from the Cummins engine I have in my donor truck," Beadle said. "No corners cut and nothing withheld from this being like a new engine."

"The fuel pump and injectors were rebuilt and set up at Pittsburg Power," said Beadle. "All my internal parts came from them as well." Pittsburg Power also set the engine up to push 450 horse. "Those who are familiar with Pittsburg Power know that they know their stuff. I'm looking forward to feeling this engine go to work." It's got $2,500 worth in powder coating on it, too, to "ensure that this engine won’t peel paint."

"The fuel pump and injectors were rebuilt and set up at Pittsburg Power," said Beadle. "All my internal parts came from them as well." Pittsburg Power also set the engine up to push 450 horse. "Those who are familiar with Pittsburg Power know that they know their stuff. I'm looking forward to feeling this engine go to work." It's got $2,500 worth in powder coating on it, too, to "ensure that this engine won’t peel paint."

"As it was an irrigation motor, some of the components were not applicable to a chassis-motor application," Beadle said, "but I had the front engine mount, rear bell housing and several other model and Peterbilt application parts from my parts donor truck to pull this off. ... It has a new clutch and reworked flywheel as well."

"As it was an irrigation motor, some of the components were not applicable to a chassis-motor application," Beadle said, "but I had the front engine mount, rear bell housing and several other model and Peterbilt application parts from my parts donor truck to pull this off. ... It has a new clutch and reworked flywheel as well."

Congrats, Zach, on a job well done. I hope the first weeks out have gone smooth as the powder coat on the block.

Read more in the "Highway Hacks" series of solutions to common problems via this link. Got an idea you'd like to share in the series? Email me directly via tdills [at] randallreilly.com.