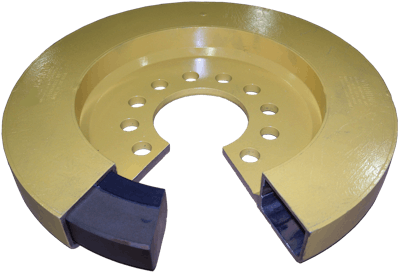

It is the barbell-looking “weight” on the front of the crankshaft near the front of the engine. There is a free-floating ring of steel (inertia ring) inside the damper housing.

It is the outside housing that does the majority of the moving on dampers, which are wear items. The inertia ring moves back and forth (clockwise to counter-clockwise) while “floating” in a layer of silicone, which leaves the housing free to turn along with the crankshaft.

When the inertia ring ceases to float independently of the crankshaft’s rotation, the damper needs to be replaced.

What causes damper failure?

Dampers can fail two ways. The first enemy is common to all wear items – time. At about 500,000 miles, silicone tends to harden. The harder the silicone, the less functional the damper.

The second cause of failure is droppage. Dampers weigh about 44 pounds and look much sturdier than they are. Its own weight is enough to dent a damper if it falls.

Once, when photographing a damper (for our first parts catalog in 2007) we dropped one and had to send it back to the manufacturer to have it checked. This was a U.S.-made piece, too.

When should a damper be replaced?

Replace your damper when you top 500,000 miles. It’s not worth the risk to go much beyond that. Short of sending it in to be checked (which, including shipping, costs more than buying a new one), you can’t see if the torsion ring can still turn freely.

If the damper is dented, it definitely needs to be replaced.

Why should I replace a damper?

The price of a rebuild is much greater than the price of a new damper – $14,000-$24,000 vs. $325-$550. Without a properly functioning damper, the crankshaft is much more likely to break.

Moreover, engine vibration without a good damper can lead to failure of many other parts, like the camshaft, accessory drive shaft, springs, flywheel bolts and flywheel housing.

You don’t want anything shaking your engine, and you don’t want your engine shaking you.

Lastly: When installing a new damper, also add a new mercury-filled engine balancer. The mercury in the balancing ring balances the crankshaft, connecting rods, pistons, flywheel, clutch and pressure plates. The smoother the engine, the longer you can drive it without getting fatigued.

-Bruce Mallinson is the owner of Pittsburgh Power, an engine performance shop in Saxonburg, Pa.