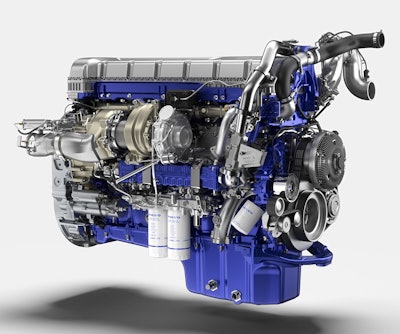

Volvo Trucks North America recently debuted the next generation of its turbo compound technology. The evolution has improved fuel efficiency over the current D13TC, 13-liter turbo compound engine by 3%. What’s more, the new engine delivers up to 11% fuel savings overall compared with model-year 2015 trucks, Volvo said.

Other improvements include enhanced efficiency over a wider range of applications, more engine ratings and a new EE Extra Efficiency drive mode. The new D13TC will be available for order later this year and go into production at the end of the first quarter of 2020.

Other improvements include enhanced efficiency over a wider range of applications, more engine ratings and a new EE Extra Efficiency drive mode. The new D13TC will be available for order later this year and go into production at the end of the first quarter of 2020.Since the first-gen turbo-compounding engine was developed in 2017, said Volvo Trucks North America Product Marketing Manager John Moore, almost 300 million miles have been logged with the new technology, validating the up to 8% fuel-savings benefits over the prior generation of Volvo’s 13-liter engine.

The added 3% fuel-efficiency benefit, Moore noted, could save $1,200 year in fuel for the average truck, based on current fuel averages and 125,000 miles per year.

The truck maker is targeting owner-operators specifically with the fuel-efficiency-improvement message through its new “Cash Machine” campaign. Customers meet “Bob,” a fictional owner-operator whose fuel economy is so significantly improved that he’s able to “spend the money saved on his high-end lifestyle,” Volvo notes. Said Fredrik Klevenfeldt, Volvo Trucks North America’s direct of brand and marketing communications: “Fleets and professional drivers in the trucking industry have important and demanding jobs and work hard every day delivering goods and services across North America. I think our customers deserve entertaining industry-related content in order to share a smile once in a while.” No matter where “Bob” stops on his route, he’s given VIP treatment, from gourmet lunches at his favorite truck stop to high-end treatment at the barber shop. He hauls in a gold-plated Volvo VNL. You can view video associated with the campaign via this link.

The truck maker is targeting owner-operators specifically with the fuel-efficiency-improvement message through its new “Cash Machine” campaign. Customers meet “Bob,” a fictional owner-operator whose fuel economy is so significantly improved that he’s able to “spend the money saved on his high-end lifestyle,” Volvo notes. Said Fredrik Klevenfeldt, Volvo Trucks North America’s direct of brand and marketing communications: “Fleets and professional drivers in the trucking industry have important and demanding jobs and work hard every day delivering goods and services across North America. I think our customers deserve entertaining industry-related content in order to share a smile once in a while.” No matter where “Bob” stops on his route, he’s given VIP treatment, from gourmet lunches at his favorite truck stop to high-end treatment at the barber shop. He hauls in a gold-plated Volvo VNL. You can view video associated with the campaign via this link.The new D13TC offers three individual drive modes, Dynamic Torque, an additional 405 horsepower rating, and the next evolution of Volvo Trucks’ patented wave piston design, the company says. These updates enable further-increased fuel efficiency over a wider range of loads, vehicle speeds and engine RPMs. This offers a broader use of applications compared with the first generation of the D13TC engine, which was designed specifically for over-the-road, long-haul applications with trucks loaded at 80,000 lb. (According to the engine brochure, the D13 with Turbo Compounding is available from 405-455 hp with up to 1,850 lb-ft. of torque. The engines work together with the Volvo I-Shift for maximum efficiency and performance by utilizing peak torque down to 900 RPM.)

The three individual drive modes available with the new D13TC engine are Extra Efficiency, Economy and Performance. These modes will enable the driver to better optimize fuel efficiency for the vehicle with desired performance, depending on application, topography and driving conditions. This new engine also features a wider RPM efficiency band, which enables top fuel efficiency for longer periods of time, Volvo says.

Dynamic Torque is an incremental torque system designed to provide the right torque at the right time. Rather than operating in silos of high-torque and low-torque modes, Dynamic Torque automatically sets a torque level dependent upon the weight of the truck, the grade and the road conditions at any given time. Volvo says Dynamic Torque also features an automatic 12th gear lockout on heavy loads with adaptive gearing engine ratings.

A kick-down switch, along with performance drive mode, allows access to full torque for customers requiring it on demand. This simpler, more effective system on the new D13TC engine will provide an even more consistent improvement in fuel efficiency across different applications, enabling customers to cut costs on a wider range of operations, the company says.

The new engine also features a revised wave piston, designed and patented by Volvo Trucks. The improved design optimizes wave technology to evenly distribute the air/fuel mixture in the cylinder, burning the fuel more consistently than a traditional piston. Volvo says the design increases the compression ratio from 17:1 to 18:1 while maintaining up to a 90% reduction of soot in the cylinder, further improving fuel efficiency in the engine.

“The individual drive modes allow drivers new heights in fuel efficiency without sacrificing performance. We are also taking it to the next level with a simpler torque package that delivers the right torque at the right time,” Moore said. “Not only is it cutting edge when it comes to sustainable use of diesel in the transportation industry, but it is the most fuel efficient Volvo engine on the market for our customers, with trucks running cleaner at a reduced cost.”