For truck drivers and owner-operators, we can't overstate the importance of maintaining proper tire pressure.

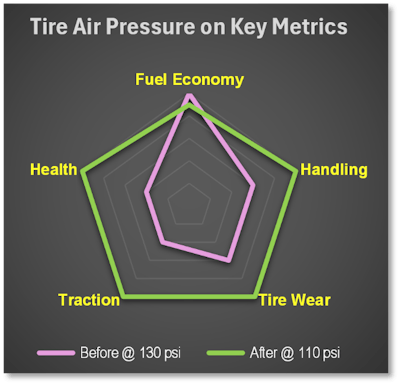

Tire pressure impacts fuel economy, vehicle handling, traction, tire life, ride quality, maintenance costs, and even the health and well-being of the driver. Understanding impacts will help yield safer journeys and more economical operation, with tire maintenance a top priority.

Tire construction

Let’s lay down some fundamentals regarding tire construction. A tire's much more than a big black donut made of rubber!

For the purpose of simplification, a tire is made up of sidewalls and tread. The sidewalls support the vehicle above the ground by creating a balloon using the sidewalls, tread rubber, and rim. The tread is literally where the rubber meets the road, providing traction for steering and propelling the vehicle. Each component has its unique construction with specific rubber compound, steel and synthetic construction materials.

Balancing multiple tire characteristics is a multi-dimensional challenge. For example, depending on the weight of the load that’s put on the tire and its specific load-carrying capacity, a commercial truck tire might have, for example, 14, 16, or 20 plies (or ply equivalents) in the sidewall.

A tire’s tread section features a tread design pattern, compounds, and other unique characteristics specific for its intended function. For example, steer tires are largely of ribbed design, with voids to absorb water to prevent hydroplaning. A drive tire has another challenge -- withstanding the high torque applied to it. Drive tires feature their own unique tread designs for maximizing traction or for low rolling resistance, depending on the tire's intended utility. Trailer tires are usually designed for minimal rolling resistance and wear, given the need for traction grip is all but non-existent.

When setting pressure in a tire, if you're deviating from the manufacturer’s load inflation table, you must consider how a tire is constructed and why those tables list the values they do. All attributes involve a balancing of -- or compromise between -- wear life, traction, and fuel economy.

Proper pressure will help owners find the balance necessary for tire longevity and performance.

Proper pressure will help owners find the balance necessary for tire longevity and performance.

Tire pressure and vehicle handling, traction

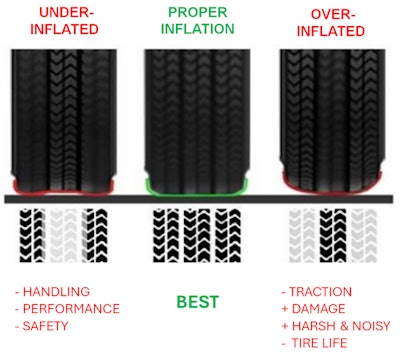

Proper tire inflation pressure ensures the truck maintains optimal contact with the road, crucial for steering responsiveness and overall maneuverability. Underinflated tires deliver sluggish handling, making it difficult to navigate turns or react quickly in emergency situations. Conversely, overinflated tires reduce the contact area with the road, leading to a loss of traction. This is especially important to consider in adverse weather conditions, where good traction is vital for safety. Maintaining the recommended tire inflation pressure can significantly enhance driving performance, leading to smoother and more controlled handling.

Among the hyper-fuel-economy community, many folks state they prefer to inflate at least 10 psi above the max tire pressure listed on the sidewall. The theory is to make the tire as hard as possible to reduce rolling resistance by adding more air pressure and stiffening the sidewall. This practice, however, has unintended consequences. Overinflation means less tread contacting the road, reducing tread traction. Coincidentally, concentrating tire pressure over a smaller surface area results in a noisier ride. And with higher pressure stiffening the sidewalls, the driver will experience a harsher ride, too, with micro shocks to the driver’s body also assaulting the bladder.

Proper pressure makes the truck drive truer, with fewer meandering steering-wheel inputs, less jostling from steering hyper-response and counter-steering. Generally, the truck feels more planted.

An overinflated tire’s pressure acts on its weakest point, which is a tire’s tread -- the sidewalls are much more stiff. A tire’s sidewall is what supports the tire above the ground. A stiff sidewall prevents the tire from rolling over its side, and reduces bulging of the sidewall, giving the driver more responsive handling.

Underinflation is also problematic, as it can produce a sluggish response and compromises the integrity of the sidewall.

As I mentioned above, tire manufacturers publish load inflation tables to help match pressure to the load put on the tire. For example, Michelin conveniently has its tables on their website, from which I took an excerpt using our steer tires as an example.

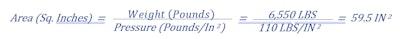

The table here shows that a 295/75R22.5 X Line Energy Z+ LRH (load rating H = 16-ply) steer position tire at 110 psi is good for up to 6,555 pounds per tire or 13,110 pounds per steer axle.

The table here shows that a 295/75R22.5 X Line Energy Z+ LRH (load rating H = 16-ply) steer position tire at 110 psi is good for up to 6,555 pounds per tire or 13,110 pounds per steer axle.

A 6x2 tractor with a 14,600-pound rated steer axle would need 123 psi. Note that in order to fully leverage our Purple Haze 6x2 trucks to 14,600+ pound steer axles, we chose a 365/70R22.5 tire size with sufficient capacity -- a size that we can expect to become increasingly popular as people better understand the benefits of a 6x2 configuration and shifting more weight to the steer axle to maintain a tight trailer gap. That size choice also contributes mightily to increased fuel economy. I only mention this as an important consideration as to which tire and what tire pressure is required to support its intended load weight.

Some simple math indicates that 6,555 pounds at 110 psi produces a contact patch area of 59.6 square inches:

Overinflating, say, to 130 psi in this 6,555-pound steer tire example, reduces the same contact area to 50.4 square inches -- a 15% reduction. This contact patch reduction changes the contact patch’s shape from a roughly rectangular box shape to a more oval shape that comprises handling, ride quality, tire wear, and driver comfort and health.

I have even heard cases where over-inflation caused one truck manufacturer’s shock mounts to fail, while others have experienced the shock’s mounting bolt's shearing failure. Talk about unintended consequences!

Lastly, during Winter months where I ascended I-70 west into High Country and back on a daily basis, traction on snow, ice, and packed snow and ice is paramount. In my duty cycle, over-inflation is potentially dangerous. As professional drivers, we need to exercise professional judgements where compromising traction is ill-advised.

The author's view January 2025, Wyoming, I-80, on black ice. This is not the place to compromise tire traction.

The author's view January 2025, Wyoming, I-80, on black ice. This is not the place to compromise tire traction.

Proper pressure and tire life, wear

Tire pressure directly impacts wear and longevity. Tires that are consistently underinflated tend to wear down faster on the edges, while overinflated tires may show signs of wear in the tread's center. When an overinflated tire’s central treads “bulge” out in the center, the shoulders have a comparatively smaller circumference, requiring the shoulders to slip during the tire’s rotation, producing funky shoulder wear to keep up with the larger-circumference center.

Both of these scenarios shorten the life of the tire, increasing the frequency of replacements and leading to higher operational costs.

By regularly checking and adjusting tire pressure, owner-operators will maximize tire lifespan, ensuring the best return on the investment.

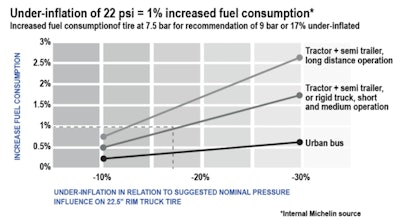

Meanwhile, consider the reality of the fuel-economy benefit of overinflation -- the following table from Michelin helps point the way forward.

As illustrated in part in the chart above, Michelin found that roughly 22 psi provides a 1.5% gain or loss in fuel economy when applied to all tractor and semi-trailer tires in a long-haul duty cycle. As a result, the operator will likely see just 0.15 mpg worth of a change, which for all intents and purposes is:

- Undetectable in day-to-day fuel economy data, and

- At today’s fuel prices amounts to less than $611 per year in fuel savings.

Such meager annual fuel savings cannot possibly justify abusing a $10,000 set of tires if it doesn’t last even a tenth of the time required to break even. Such a practice is financially unjustified.

Ride quality, health impacts for the truck’s operator

Maintaining correct tire pressure also impacts ride quality and drivers’ health and well-being.

Underinflated tires can lead to a mushy feel when driving. On the other hand, overinflation can result in a jarring experience, where drivers more acutely feel even minor road imperfections, particularly uncomfortable during long hauls. Back pain can result, likewise fatigue, both detrimental over prolonged periods of driving, and especially so over the course of years. Consistent vibration can contribute to the development of more serious musculoskeletal issues.

A smooth ride enhances comfort for drivers but also aids concentration and alertness, both crucial for safety during long hours on the road.

My recent personal experience came while upgrading tires on our 2024 Volvo “Blue Nova,” with a 13,200-pound-rated steer axle and 17,000-lb.-max rated tandem drive axles. We went from one set of steer tires at 130 psi to new steers set to 110 psi. Using Michelin’s load-inflation chart informed adjusting the original 6x4-configured dual drives from teeth-rattling 130 psi to a new set at 100 psi.

First, the ride quality drastically improved! Even though we have Link Mfg’s state-of-the-art ROI Cabmate electronically-controlled dynamic suspension on the rear of the cab, the steer axle does not have such an advantage. As a result, the previously over-inflated steer tires transmitted all of the road “imperfections” through the tires, to the suspension, to the frame, to the steering wheel and to the driver’s seat, mitigated slightly by the Volvo seat’s air suspension.

The author's "Blue Nova" 2024 Volvo 6x4

The author's "Blue Nova" 2024 Volvo 6x4

Second, the stress of poor vehicle handling heightens mental fatigue, making it more difficult to maintain focus and make safe decisions on the road. Since it was common, I did not appreciate how much road construction inflicts jostling and counter-steering when overinflated tires cause the tires to overreact. As a driver, I did not realize how stressful that was until after I correctly set the steers’ pressure to 110 psi.

After making the switch to the Michelin tires and setting all the tires’ pressure correctly, consistent to the tire maker's load-inflation tables matching inflation pressure to the load weight, I felt much more relaxed at the end of 11 hours of mountain driving. What a huge improvement in ride quality, comfort, and those beneficial health aspects. No significant whole-body vibration, and much less stress.

In conclusion, prioritizing tire maintenance and adhering to proper pressure guidelines can significantly reduce discomfort and the potential for adverse health impacts.

Make tire pressure checks and adjustments a part of your daily pre-trip routine. You’ll ensure safer and more efficient hauls while also increasing your bottom line through reduced operating costs. Remember, a well-maintained truck is not only a safer truck but a more profitable one.

Perhaps more importantly, properly set tire inflation and you’ll stand to deliver big on quality of life in the short- and long-term, too!

[Related: In a tough trucking-business environment, owner-operator must improve efficiency to compete]

The author of this story, Alec Costerus, was among semi-finalists in Overdrive's 2024 Trucker of the Year competition. Costerus is a longtime owner-operator and advocate for professional drivers with more than a million miles behind him. He's Vice President of the Alpha Drivers Transportation business, and additionally is co-founder and director of Alpha Drivers Testing & Consulting, a transportation industry educational provider, technical advisory, and business consulting firm (also a proud Michelin partner). He serves in that capacity as an Administrator of Volvo Truck Masters, Mack Anthem Truck Masters, and related Facebook groups. He holds dual B.S. degrees in Chemical Engineering and Geology from Tufts University and completed an Executive Program in Finance at University of Virginia’s Darden Business School.