Every owner-operator knows today's trucking business environment is challenging, at best. Between global forces pulling on demand for goods and diesel, and a glut of trucking capacity outpacing demand, plenty forces are at work that no individual owner-operator has control over. Yet we do have 100% control of how we manage our business.

Today, with relatively low freight rates coupled with high fuel costs, are you still running your business the same way you did during the good, booming years? If the answer is yes, it’s high time to change gears.

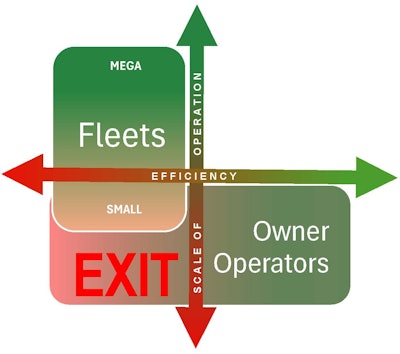

To compete with large fleets that have an economy of scale advantage based on sheer size, owner-operators must leverage inherent operational efficiencies. By definition, owner-operators lack the scale advantage. Those without a durable competitive efficiency will inevitably find themselves with neither a scale advantage nor an operational advantage.

Inefficient owners will find themselves in the lower-left quadrant on the chart and at the mercy of the market or heading to the exit -- whether by choice or as a victim of getting culled from the herd.

Inefficient owners will find themselves in the lower-left quadrant on the chart and at the mercy of the market or heading to the exit -- whether by choice or as a victim of getting culled from the herd.

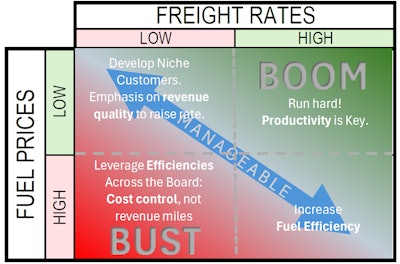

In the booming good times mid-late 2020 through 2021, with high freight rates and relatively low fuel cost, it made perfect sense for owner-operators to focus on high productivity. The strategy was to run fast to maximize revenue. Back then, it was OK to run harder, even if less efficiently, as high rates more than offset the higher fuel costs of greater speed.

Efficiency is always important for a business owner, and remained so during the boom time. Yet then, it was a secondary consideration, as illustrated in this figure.

Efficiency is always important for a business owner, and remained so during the boom time. Yet then, it was a secondary consideration, as illustrated in this figure.

Today, however, small trucking businesses need to shift gears to adjust to steeper terrain. The one-two punch of low rates and high fuel sets the foundation of a bust! Here, the ideal strategy shifts to reducing expenses. Though evidence exists that the opposite has taken place for many owner-operators now running more miles than during the pandemic boom years, running more miles should now be your last strategy.

The aim is to work smarter, not harder!

There are two ways to do this:

- Increase the quality of the revenue, not the quantity of revenue miles.

- Increase your business’s efficiencies -- both fuel efficiency and operational efficiency.

This way you attack the current bust market on two fronts by moving from high fuel costs to lower fuel cost per mile, and increase the freight rate per mile by improving the quality of the rate. (Ways toward the latter, some of which I'll expand on below: Expanding your niche market capabilities; transitioning from live load/unload loads to power-only drop and hook loads; moving from solo driver to team operations; addressing customer challenges with driver assist, after-hours driver unload, cross border, etc.; or another operational shift.) If you want to transition from the bottom-of-the-barrel freight rates offered in markets where price is virtually the only competitive consideration, the bread and butter of many large fleets, you’ve got to move out of their lane and leverage your own capabilities.

Equipment can help, but that’s not the end of the story

Optimized vehicle specifications can help deliver maximum fuel economy. Spec’d as aerodynamically as possible, including the trailer in that calculation, our “Purple Haze” 2023 Volvo VNL 760 can pull 80,000 lbs. GCVW at 800 rpm at 55 mph. An efficient truck/trailer combo will turn high fuel prices into profit.

The fast rear axle ratio (RAR) allows the Volvo I-Torque spec to comfortably run long distances at a reduced piston speed, better matching power generated to power required, to achieve superlative fuel economy.

The fast rear axle ratio (RAR) allows the Volvo I-Torque spec to comfortably run long distances at a reduced piston speed, better matching power generated to power required, to achieve superlative fuel economy.

Yet getting equipment specs in line isn’t the only answer to the question of how to improve efficiency. Goals there also require a mind-set for proper load selection and realistic dispatching that accounts for lower average speeds, speed management to reduce changes of inertia, and proper driver behavior during non-driving periods. (Use those APUs, eAPUs, bunk heaters, solar panels to charge the batteries, etc.)

[Related: Paths to 10+ mpg in a Class 8 diesel tractor with aero, downspeeding, more]

Based on years of experience, we consistently achieve hyper-fuel efficiency because we strategized, designed and implemented plans to attain that goal. Moreover, we routinely offer these keys to success to help others become more profitable in their business operations:

- Proper truck specs prevent piss-poor fuel economy. Don’t drive beyond your truck’s specs. Today’s goal is to run efficiently, not fast! We spec’d for our on-highway specific duty cycle all of the following: engine, transmission (Volvo I-Shift automated manual), fast rear axle ratio of 2.16, aerodynamics, 6x2 configuration with liftable axle, driveline, tire selection (tread design for low rolling resistance, purpose), non-torque reactive suspension, fifth wheel placement, lubricants, fuel additives … This list goes on. The Volvo I-Torque specs provide drivetrain versatility that allows the truck the ability to perform multiple roles without needing to swap trucks. Thus: No compromise between productivity and efficiency!

- Use preventive maintenance to maintain “optimal” specs, not simply factory specs. Have an annual maintenance program that proactively maintains your livelihood’s equipment in top-performing condition.

- Drive as slowly as possible, and only as fast as necessary. Why drive faster only to waste fuel, and to wait longer at the destination? Optimize the situation! Ask whether running faster is justifiable in today’s freight markets, whether you have appointments and/or have not already secured the next load. Evaluate the cost of increased productivity against the cost saved with increased fuel efficiency.

- Match average dispatch speed to the time and distance allotted for any move. The average dispatch speed is the number of miles from shipper to receiver divided by the dispatched available hours to complete the run between scheduled/appointment times. This includes all stops, breaks, rest periods, etc. It’s important to distinguish between cruise speed and dispatch speed. If the average dispatch speed is much more than 50 mph (requiring a cruise set speed of at least 60 mph), then this becomes a costly load to run. A load with cruise-set speed of 70 mph will only yield an average dispatch speed of 58 mph. Higher cruise speeds to meet a time crunch will degrade the profitability of the load.

- Pulling power-only loads can minimize live loading and unloading and thus detention times to maximize miles, especially with team operations.

- Pull aerodynamic trailer equipment to maximize fuel efficiency. If not aero-efficient, why bother? An aerodynamic trailer reduces the power required so you can operate more efficiently by only generating the power needed, which may allow for staying in top gear longer.

- Optimize fuel purchases by utilizing group fuel purchasing power by buying fuel in-network and then, within that network, at the cheapest ex-tax price along route. Remember that fuel expense is the product of two factors: purchased fuel quantity and net fuel price. See National Association of Small Trucking Companies members’ savings, like other large group programs. Our high fuel economy routinely saves us about $2,400 per month versus a typical truck getting 7 mpg, while our fuel discount program saves an additional $600 and more. Who cannot benefit from saving $3,000 or more monthly per truck?

- Develop a deep understanding of operational data through telematics.

- Capitalize on your strengths, whether the time efficiency a team operation can bring, a specialized market niche, value-added services only a small business can offer, and/or close agent/broker relationships.

In essence, owner-operators absolutely must make or truly solidify the strategic shift from “steering wheel holding truck driver” to savvy business owner to succeed in down markets like that of the present. Otherwise, you’re better off remaining as or reverting back to being a company driver. For former owners, it could mean leveraging professional experience as a trainer for developing new drivers.

Here are a few key elements of our 2023 Volvo’s success achieving the fuel economy we have from aftermarket suppliers worth investigating:

- AirDog by Purification Systems

- Phillips and Temro Industries’ IdleFree Series5000 eAPU

- Merlin Solar

- BASF Fuel and Lubricant Solutions

- Dana driveline components, lubricants

- Link Manufacturing’s ROI CabMate cab suspension

- Michelin Truck Tires

- Michigan MD Alignment and Doctor Preload Bearing Adjustment Tools

- Hot Shot’s Secret diesel treatments Diesel Extreme, FR3, LX4, etc.

- National Association of Small Trucking Companies’ fuel purchase discount program

- Volvo Trucks North America’s I-Torque spec

Find more information on controlling fuel costs in Chapter 5 of the updated Overdrive/ATBS-coproduced "Partners in Business" book for new and established owner-operators, a comprehensive guide to running a small trucking business sponsored for 2024 by the Rush Truck Centers dealer network. Click here to download the most recent edition of Partners in Business free of charge.

Find more information on controlling fuel costs in Chapter 5 of the updated Overdrive/ATBS-coproduced "Partners in Business" book for new and established owner-operators, a comprehensive guide to running a small trucking business sponsored for 2024 by the Rush Truck Centers dealer network. Click here to download the most recent edition of Partners in Business free of charge.