Updated August 15, 2023, to reflect the 2023 Brake Safety Week inspection event happening August 20-26, and making its focus brake linings and pads.

Ahead of the Commercial Vehicle Safety Alliance’s Brake Safety Week inspection event, approaching the week of August 20-26 across the nation, brake experts' insights and tips on one of the more common violations: brake hose chafing, might help you stay out of the weigh station for an extended stay. Hose chafing was last year's focus area for the weeklong event, during which inspectors gathered data on chafing violations while conducting the vehicle-focused portion of inspections.

Brake-related violations in general regularly make up the majority of vehicle out-of-service violations, according to the CVSA, and considering the maintenance category broadly, close to a majority of vehicle violations in some states with a brake-heavy focus like North Dakota, Montana, Virginia, California and Texas. Those five states led the nation for high percentages of brakes violations uncovered, calculated as a percent of all violations issued in the state. That's according to Overdrive's 2022 CSA's Data Trail update analyzing inspection and violation trends nationally.

As of last, though, nationally, brakes violations were on a slight downward trend as a share of the total violations.

During the Brake Safety Week blitz, inspectors will no doubt scrutinize the entire brake system, in addition to other vehicle components. In preparation, you can access prior reports on brake adjustment, adjustment and the 20% out-of-service rule, and other helpful brake-maintenance resources via those links.

But the hoses and tubes that support that overall air brake system have become of such concern for the likelihood of chafing that CVSA reports it as "one of the more common vehicle violations, and one that can affect a motor carrier’s safety rating." With last year's event, CVSA published a flyer that focused on brake hose and tubing tips with advice on chafing prevention leading the way.

This image showed an out-of-service violation for hose chafing from CVSA's flyer. "The hose should be replaced if damaged," said Brian Screeton, supervisor of technical service training at Bendix Commercial Vehicle Systems. "If it is caught early enough and the hose is not damaged, correct the hose routing or install the proper length hose if the wrong length has been installed."

This image showed an out-of-service violation for hose chafing from CVSA's flyer. "The hose should be replaced if damaged," said Brian Screeton, supervisor of technical service training at Bendix Commercial Vehicle Systems. "If it is caught early enough and the hose is not damaged, correct the hose routing or install the proper length hose if the wrong length has been installed."

“Chafing of an airline is typically from the line rubbing or touching something that leads to this kind of wear,” said Joe Kay, drivetrain engineering director at Meritor. “Air lines can also see damage from being bent and flexed constantly, which is a form of fatigue.”

Life on the road is tough. With trucks constantly hitting the highways, components like the chassis, suspension, powertrain and others (including brake hoses) are subject to movement, which can provide opportunities for chafing if hoses are not carefully routed and properly attached.

“Anytime hoses are permitted to move, there is potential for lines to rub,” said Transervice vice president of maintenance Matt Copot. “There are also times when objects might move brackets and create issues where lines are now touching as a result of brackets being moved and/or broken away.”

A trooper with the Florida Highway Patrol holds up a chafed brake hose during a Level 1 truck inspection (see the video posted below), which resulted in a violation that did not place the truck out of service, in this case. Other violations can be more severe. "Oftentimes the air lines will be held to a frame or structural member with flexible springs or tie-offs," said Joe Kay, drivetrain engineering director at Meritor. "Make sure these are in good condition to assure the air lines don’t drag on the ground or rub on objects that can chafe. Trailers tend to have longer air lines, especially on slider suspensions."

A trooper with the Florida Highway Patrol holds up a chafed brake hose during a Level 1 truck inspection (see the video posted below), which resulted in a violation that did not place the truck out of service, in this case. Other violations can be more severe. "Oftentimes the air lines will be held to a frame or structural member with flexible springs or tie-offs," said Joe Kay, drivetrain engineering director at Meritor. "Make sure these are in good condition to assure the air lines don’t drag on the ground or rub on objects that can chafe. Trailers tend to have longer air lines, especially on slider suspensions."

In addition to movement, improper brake hose length can also lead to chafing.

“If a replacement brake hose is installed and it is too long, it will be hard to install without there being a possibility of chafing,” said Brian Screeton, supervisor of technical service training at Bendix Commercial Vehicle Systems. “The correct length hose should always be used."

So who’s installing the wrong-sized brake hose which can lead to a costly OOS violation? It’s not the truck OEMs.

“By far, most hose chaffing issues are caused by previous repairs,” explained Daniel Mustafa, director of technical service at Travel Centers of America. “When a truck technician does not reinstall the various clamps and routing hardware it allows the hose to move in a way that the manufacturer did not intend.”

See how each state stacks up with this comprehensive report

Understand your inspection risk with these national rankings for inspection intensity, highly variable across the United States, as well as where an inspection is most likely to result in a violation in this report from the editors of Overdrive and CCJ in partnership with sister data company RigDig.

Download the report to access state-by-state insights on:

• Moving violations, such as speeding

• Hours of service

• Brakes, lights and other vehicle violations

• Clean inspections

• Violations per inspection

Inspect and correct

Inspecting and replacing damaged brake hoses during pre- and post-trip inspections is the best way to avoid costly violations. Chafing leaves behind some pretty noticeable clues, as most inspectors will attest.

“By conducting routine visual inspections, most damaged lines that have occurred from rubbing can be seen,” Kay said. “Typically, it’s a color difference or the hose may not appear to be round where it touches an object. Look at the ends where the connectors are for damage due to flexing or the organic material stretching and ripping.”

Knowing where to look can make all the difference.

“Lines that are not located close to frame rails or on the upper interior side of channels are more prone to having chafing issues,” Copot explained. “In addition, lines that span open areas or provide for movement will be prone to chafing. Look at these areas as opportunities to provide spacing or even rerouting options to eliminate the potential of chafing, which lead to increasing CSA scores.”

Brake hose/tubing-related violations in general are a middle-grade severity weight of 4 (out of a possible 10) in the CSA Safety Measurement System methodology. If the violation results in an out-of-service order, such as in the picture above showing chafing that exposes the reinforcement ply of the hose, add another two points for a weight of six.

Improperly repaired brake hoses can lead to out-of-service violations, as CVSA makes clear with this image, also from its flyer.

Improperly repaired brake hoses can lead to out-of-service violations, as CVSA makes clear with this image, also from its flyer.

Screenton advised to conduct periodic inspections to ensure that tie straps, clips and brackets that support hose routing are not damaged or broken. Also, carefully follow hose paths to check for possible friction points.

“Look for hoses that are close to and part of the chassis or axle,” Screenton said. “When inspecting a hose, even if is not touching anything, keep in mind that the axle will be moving relative to the chassis.

“If the hose is close but not touching when the vehicle is parked during an inspection," Screenton continued, "does the hose have enough clearance when the vehicle is in operation and the chassis, axle and suspension are in motion?”

With improper repairs causing most hose chafing issues, Mustafa recommends being especially diligent following a repair by asking three questions, which may make the difference in keeping a truck on the road or getting it grounded with a costly violation: “Are all clamps and routing hardware in place? Do the hoses seem to be routed in a way that will prevent the hoses from contacting moving parts? Do the hoses seem to be excessively loose or tight, which would be evident from the lines being excessively loose or tight?”

In addition to looking for damaged lines and supporting hardware, including hose springs, look closely at air pressure readings and listen up.

“The best is conducting visual inspections like looking for worn surfaces but also listening for air leaks, and monitoring your air gauges to ensure excessive air is not being consumed, and replacing anything suspicious,” Kay said.

[Related: Stay ahead of the inspectors with this collection of maintenance-related coverage in Overdrive]

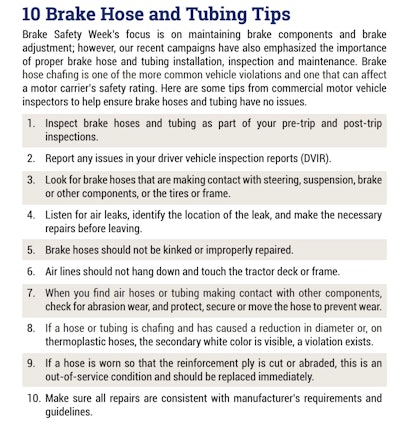

CVSA offered these 10 hose/tubing tips in its flyer. "It’s important to make sure there is adequate length of brake line so the suspension can move up and down in travel and on steerable axles the knuckle can make full rotations without pulling on the line," said Joe Kay, drivetrain engineering director at Meritor. "As air disc brake pads wear, the caliper will need to move at least 1-inch to accommodate the wear so the line length needs to be assured."

CVSA offered these 10 hose/tubing tips in its flyer. "It’s important to make sure there is adequate length of brake line so the suspension can move up and down in travel and on steerable axles the knuckle can make full rotations without pulling on the line," said Joe Kay, drivetrain engineering director at Meritor. "As air disc brake pads wear, the caliper will need to move at least 1-inch to accommodate the wear so the line length needs to be assured."

--Todd Dills contributed to this report