Updated August 27, 2024, to reflect this year's Brake Safety Week initiative and to include CCJ's recent 20% rule discussion, embedded below.

With the Commercial Vehicle Safety Alliance's Brake Safety Week 2024 under way through this coming Saturday, listen back to the 2021 Overdrive Radio podcast talk with Pennsylvania-based former local-department officer and long-certified DOT inspector Andy Blair (embedded above and below). Looking at the landscape for commercial truck inspections generally, Blair sees plenty missed opportunities when it comes to troopers helping truckers with out-of-service violations. All too frequently, violations that put an owner-op or other driver out of service simply aren't explained at the point of inspection. Too many trucking companies large and small don't invest in the CVSA out-of-service criteria handbook, the only place you'll find those criteria in all their minutiae, according to Blair.

[Related: Refresher on the OOS violations for hours of service, lights]

The equipment category that takes up the largest number of pages therein? Brakes, of course, and specifically clamp-type drum brakes. In this edition of Overdrive Radio, Blair runs us through the specifics of the "20% rule" when it comes to clamp-type brake adjustment, among the most common of brake violations. Fundamentally, as he outlined in a document that's excerpted here below, if 20% or greater percentage of a truck's brakes are defective, that unit is out of service:

What makes a brake defective in the OOS criteria:

- Absence of effective braking action when the service brakes are applied.

- An audible leak at an air brake chamber.

- A missing brake on any axle required to have brakes.

- The air brake is at least 1/4” beyond its maximum legal stroke.

Our colleagues at Overdrive sister publication CCJ August 16 published this talk with CVSA about the 20% rule, too, detailing a lot that's here:

For most of the owner-operators reading here, that 20% rule could apply to the tractor alone in a tractor-trailer combination with just two brakes. It could theoretically apply to a standard tandem-axle trailer all by itself with just one brake so far out of adjustment to be considered defective. (At once, Kansas trooper and Public Information Officer Nick Wright points out that scenario is impossible for a trailer inspected en route given it has to get to the inspection site hooked to a tractor -- "The 20% rule is calculated on all brakes on the combination as it comes to us, meaning at the time of inspection," he said. "So on a 5-axle [tractor-trailer combination], it takes two full brakes ... to put the combination OOS. All vehicles that contribute to the 20% criteria must be declared out of service." If the trailer contributes with one brake, the tractor must be too. Both vehicles would be shut down.)

To get to the full-brake-defective judgment by adjustment alone, push-rod travel must be at least a quarter-inch beyond the maximum legal stroke. If just 1/8-inch beyond, that would be seen as a "half brake." Two halves, as in basic math, do indeed equal one full in the out-of-service criteria, according to Blair.

Get four brakes on a 10-brake combination all just 1/8-inch out of adjustment? Four half brakes equals two full, or 20% of the 10 brakes on the combination. You just got yourself a mandated break and roadside repair.

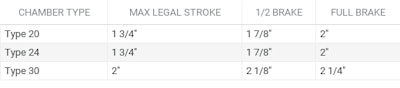

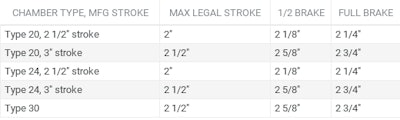

Vetting the work of an officer, though, requires first knowing the specs of your own brake chambers and clamps -- for different brake sizes and types, there are different maximum stroke lengths. Following find charts based on the OOS handbook's outline for the most common brake chamber types, in both regular (some say short) stroke and long-stroke varieties.

Air brake stroke -- regular (short) clamp

Long-stroke

Blair has seen officers mess this up more than once -- enforcing pushrod length assuming they were looking at a regular clamp system when it reality it was a long type. Blair handles DataQs for the big construction-trucking outfit he works for but also independent clients from time to time, and it's in that system for correcting violation data errors that evidence can be shared to remove the violation from the record.

Blair does push-rod-travel checks on trucks today, often enough by himself and using wheel chocks and other wood to keep brakes applied. Take pictures anytime you do it in case evidence of compliance could prove useful down the line. Here's the basics of that system, useful to make certain your brakes are in fact good to go, too:

The air brake test set-up

- Bring the air pressure to between 90 and 100 psi.

- Turn the engine off and chock the wheels.

- Release the parking brake(s).

- Mark the brake pushrod at its point closest to the chamber itself.

- Have the driver fully apply the brakes.

- Measure the distance the pushrod has moved out in inches.

- If the air pressure drops below 90 , restart engine and build pressure up.

- Determine from the Max Brake Stroke chart if the brake is in compliance.

Reminders:

*A FULL BRAKE is a quarter-inch or more beyond maximum legal stroke.

*A HALF BRAKE is at least 1/8” and up to 3/16” out of adjustment.

*16ths of an inch are not used to determine whether it is a FULL BRAKE or a HALF BRAKE. All brake measurements are to be made in 1/8” increments.

[Related: Toughest states for brakes violations: 2022 update, ahead of Brake Safety Week]

In addition to Blair's considered thoughts, in the wake of the podcast's original airing in August of 2021, Kansas Highway Patrol Public Information Officer and trooper/inspector Nick Wright offered some points of clarity about roadside realities when it comes to out-of-service brake adjustment, with a real-world example to illustrate it, you can read via this link.