UPDATED as of Aug. 20, 2020 to reflect continued profusion of Performance-Based Brake Testers in advance of Brake Safety Week 2020, and further information on the inspection event:

If you run in one of the many states that have one of the devices shown above — a performance-based brake tester (PBBT) — it’s likely you’ve seen one in operation. I’ve written about them before in various contexts. I know Wisconsin, Georgia, Tennessee and Florida, among others, have one or more of the units in operation. Will Schaefer, Commercial Vehicle Safety Alliance director for the Brake Safety Week effort ongoing nationally next week, Aug. 23-29, added a few names to that list of states, including one Canadian province. He spoke in an online presentation the morning of this update. PBBT machines are operational also in Alaska, Alberta, Colorado, Indiana, Kansas, Minnesota, New Jersey, both North and South Dakota and South Carolina.

CVSA describes PBBTs, some of them installed permanently (such as at the I-81 SB scale in Greene County, Tennessee) and some (like the above in Georgia) mobile units capable of deploying anywhere, this way:

A Performance Based Brake Tester (PBBT) measures the slow speed brake force and weight at each wheel, adds up the total vehicle brake force, and divides it by the total vehicle weight to determine overall vehicle braking efficiency. U.S. federal regulations and the North American Standard Out-of-Service Criteria require a minimum braking efficiency of 43.5%. If your vehicle’s braking efficiency is below 43.5%, your brakes are in need of service because they are not providing the minimum stopping power required and are performing poorly.

If you cross a PBBT and the overall braking efficiency falls below the 43.5% measure, you can be put out of service, according to the CVSA out-of-service criteria. Applicable regulatory language is spelled out in 393.52. Some of the discussion around PBBTs during past CVSA Workshop events has illustrated another thing worth keeping aware of:

Issues measuring brakes in liquid bulk applications

If you haul liquid bulk, whether in a tanker or in totes, the difficulty of obtaining accurate weights at each wheel end given the sloshing of the liquid as individual axles move over the PBBT’s roller often produces errors in readings that, if not heeded by the inspector, can be compounded as the machine makes its overall braking force calculation.

The upshot: If you’re put out of service as a result of a PBBT measurement and the inspector clearly didn’t give adequate time for the liquid to totally settle, you may have grounds for a DataQs challenge to the violation via FMCSA’s system.

At once, most inspectors utilize the PBBT as another tool in the entire Level 1 inspection, which also includes measurements of push-rod travel, visual inspection of brakes and more. If they can’t get you one way, they may get you another.

PBBTs serve something of a screening function, too. Even if overall braking force is not sufficiently low to put you out of service, force readings at individual wheel ends will show a particular brake that has issues, if they exist. Officers can then move in the visual aspects of the inspections to focus in on that brake to check for problems. Operators receive print-outs with each PBBT measurement that show individual and overall measurements. Utilize the data there to focus maintenance checks down the line for brakes not performing like the remainder.

What Brake Safety Week is tracking from a data-gathering perspective now: Chafed tubing/hoses

Inspection events like Roadcheck and Brake Safety Week serve a variety of purposes, from basically raising the profile of safety issues among industry and enforcement to serving particular data-collection and analysis efforts when it comes to safety-related outcomes of particular elements of truck equipment, as CVSA’s Schaefer explained this morning. He was delivering a presentation about Brake Safety Week that was sponsored by safety training provider Infinit-i Workforce Solutions. Schaefer detailed the history of the event, which began as a single brake-check day more than two decades ago and focused closely in data collection on out-of-adjustment violations seen on trucks with old-style manual slack adjusters and the then-newfangled automatic adjusters that are in the vast majority of units today.

For a few years the event looked closely at anti-lock braking system-related violations, and now it’s turned its attention to compromised hoses and tubes in the air-brakes system.

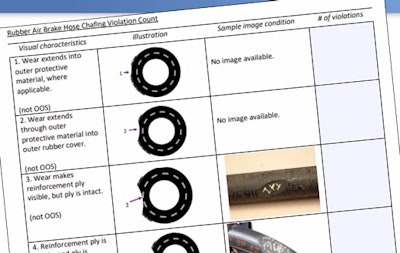

This image shows part of a checklist that states will collect from inspectors after they tally up results from the week’s worth of inspection, said Schaefer. “If there is wear that goes to the reinforcement ply level” of an air hose, “that would be a violation – if wear goes into that reinforcement ply or through it, that’s an out-of-service violation.” Where you’ll find such wear? Hoses rubbing together or on the deckplate “are a common one. Brake lines under the trailer are in the same category in the data we collect nationally. This is what we’ll be collecting this year – plus the rate of out-of-service brake violations,” the no. 1 most prevalent OOS category most years.

This image shows part of a checklist that states will collect from inspectors after they tally up results from the week’s worth of inspection, said Schaefer. “If there is wear that goes to the reinforcement ply level” of an air hose, “that would be a violation – if wear goes into that reinforcement ply or through it, that’s an out-of-service violation.” Where you’ll find such wear? Hoses rubbing together or on the deckplate “are a common one. Brake lines under the trailer are in the same category in the data we collect nationally. This is what we’ll be collecting this year – plus the rate of out-of-service brake violations,” the no. 1 most prevalent OOS category most years.If there’s any element of the braking system that will get “extra” attention during this year’s event, given these checklists will be in hand for participating officers, I’d say chafed hoses are a safe bet.

Following find a few brakes-related short videos in CVSA’s “Inspection Bitz” series — they’re intended for inspectors, but can also I’d imagine give you a window onto some of the finer points of just what officers are looking for: