Trucking news and briefs for Thursday, Aug. 17, 2023:

New heavy-haul, configurable lowbed from Fontaine

Fontaine Specialized introduced this week its new Magnitude 65 lowbed trailer.

Fontaine's new Magnitude 65 features three deck options: flat (MFLD), drop side rail (MDSR), and beam (MBMD).Fontaine Specialized

Fontaine's new Magnitude 65 features three deck options: flat (MFLD), drop side rail (MDSR), and beam (MBMD).Fontaine Specialized

The 3+2 modular multi-purpose trailer is designed and built to efficiently transport a wide array of loads, featuring three distinct deck options: flat (MFLD), drop side rail (MDSR), and beam (MBMD).

“The Magnitude 65 truly embodies versatility in heavy-haul lowbeds," said Heather Gilmer, Fontaine’s vice president of sales. "It accommodates loads of up to 65 tons in 16 feet as a 3+2 or can be configured with five close coupled axles to transport up to 70 tons in 12 feet.”

Gilmer added that the trailer features a hydraulic detachable gooseneck and a tridem bogie, each of which offer seven ride height positions. “This heightened flexibility proves indispensable for operators navigating heavy loads across obstacles or beneath bridges," she said.

Manufactured using 100,000-pound minimum yield steel main beam flanges, the Fontaine Magnitude 65 is designed to provide years of strong, dependable service, the company said.

The flat and beam decks feature a 24-inch loaded deck height, while the drop side rail deck takes it down to 15 inches. At full load, all of the modular decks provide 6 inches of ground clearance.

Fontaine also offers a wide variety of attachments and components, such as jeeps, flip boxes, spreaders and flip axles. A Fontaine dealer can help tailor a Magnitude 65 to fit a specific application.

[Related: Now that's 'high, wide and ugly': Three companies recognized for historic specialized moves]

Bendix brake-inspection tips ahead of Brake Safety Week starting Aug. 20

“What you do in the shop and during pre-trip walk-arounds -- looking at every aspect of your vehicle -- can make an important difference on the road and during a brake system inspection, simply by catching brake-related issues before they become problems.”

Mark Holley, the Bendix company director of marketing and customer solutions for wheel-end products, reiterated perhaps the best defense against brake-system violations any time of the year, more so this one upcoming.

“Your regular inspections can go a long way toward catching some obvious violations, including loose hoses or damaged components like air chambers or pushrods,” he added. Ahead of the brake blitz, the company offered a primer on daily, weekly and monthly checks of both drum and air-disc systems.

Every day:

- Check for damaged or loose-hanging air chambers, pushrods, or slack adjusters.

- Make sure slack adjusters on each axle are extended out to the same angle. Different angles can indicate an out-of-adjustment brake or a broken spring brake power spring.

- Examine tubing and hose condition, positioning, and connections.

Every week:

- Perform a 90- to 100-psi brake application with the wheels chocked and the parking brakes released, and listen for leaks.

- Check air disc brake rotors for cracks.

- Inspect drum brake linings for wear and cracks.

Every month:

- Check for moisture in the air system to prevent contamination that leads to component deterioration and system leaks.

Any time you’ve got a vehicle in the shop, it’s worth greasing the S-cam brake tubes and automatic slack adjusters. This quick process helps prevent rust and corrosion, and it helps keep the slack functioning properly.

[Related: An assist for avoiding drum-brake adjustment violations]

Key among differences between air disc- and drum-type brakes for your inspection purposes is measurement of brake stroke. Because air disc brakes include an internal adjustment mechanism, their brake stroke is not measured externally, as is the case with drum brakes.

“Measuring a drum brake’s chamber stroke is a matter of checking the distance from the air chamber to the clevis pin with the brakes released, and then again after a fully charged brake application,” Holley explained. “The difference between these measurements is the brake stroke, and its maximum length depends upon the brake chamber type and size.”

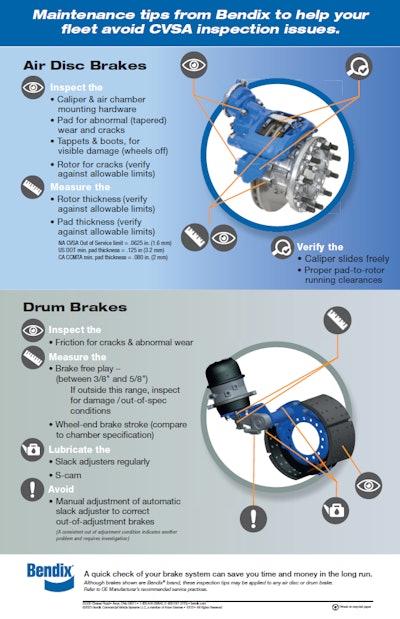

Improperly adjusted brakes can also drag -- impacting fuel efficiency and speeding up pad wear – or experience decreased stopping power. Bendix developed the following infographic to note the differing maintenance needs of air disc and drum brakes.

“Whether you’re replacing air disc brake pads or drum brake shoes, select components that will ensure the original equipment manufacturer (OEM) requirements are met so the vehicle remains compliant,” Holley said. An oil-coalescing air dryer cartridge (like Bendix's PuraGuard), he added, could help protect the air supply against corrosive oil aerosols that lead to leaks and potential violations. It’s important to note that while oil-coalescing cartridges can be used to replace standard cartridges, the reverse is not the case: You shouldn’t downgrade from an oil-coalescing cartridge to a standard.

[Related: Prime time for air disc brakes]

Werner to haul 2023 Capitol Christmas Tree

Werner will haul the 2023 U.S. Capitol Christmas Tree with a specially-decaled Kenworth 100th anniversary T680 Signature Edition.

Werner will haul the 2023 U.S. Capitol Christmas Tree with a specially-decaled Kenworth 100th anniversary T680 Signature Edition.

Werner was selected as the hauler for this year’s tree at the recommendation of Kenworth Truck Company and based on industry reputation, according to Bruce Ward, president of Choose Outdoors, the non-profit partner assisting the USDA Forest Service in coordinating the annual initiative.

The tree will be harvested from the Monongahela National Forest in early November, followed by a journey with special events in communities throughout the state before being delivered to Washington, D.C. Werner Enterprises will also deliver thousands of handmade ornaments made by West Virginians, along with smaller trees for military families stationed at Joint Base Andrews donated by presenting sponsor, 84 Lumber.

“Werner’s selection as the 2023 Capitol Christmas Tree project carrier is truly an honor and testament to our hard work in keeping America moving, no matter the task,” said Derek Leathers, Werner’s Chairman, President and CEO. “The professional drivers entrusted with this prestigious project are highly skilled and embody our core values of safety, service and leadership. They will do an exceptional job carrying out this unique project and tribute to our country.”

Werner drivers Jesus Davila and Tim Dean will do the honors of delivering the U.S. Capitol Christmas Tree to Washington, D.C., on behalf of Werner, while husband and wife team Steve and Gina Jones will transport the handmade ornaments and 84 companion trees.

A specially-decaled Kenworth 100th anniversary T680 Signature Edition will deliver the 2023 U.S. Capitol Christmas Tree. The T680 is equipped with a 76-inch sleeper and the Paccar Powertrain featuring the Paccar MX-13 engine rated at 455 horsepower, Paccar TX-12 automated transmission, and Paccar DX-40 tandem rear axles.